Page 319 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 319

Steam Turbine Best Practices Best Practice 5 .11

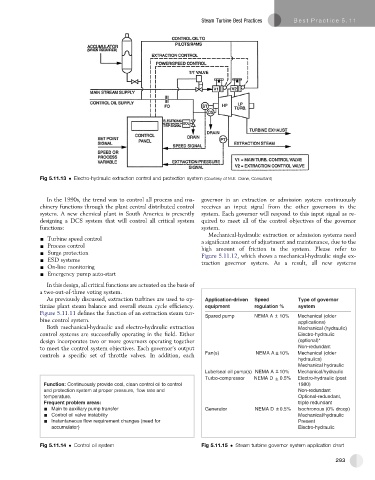

Fig 5.11.13 Electro-hydraulic extraction control and protection system (Courtesy of M.E. Crane, Consultant)

In the 1990s, the trend was to control all process and ma- governor in an extraction or admission system continuously

chinery functions through the plant central distributed control receives an input signal from the other governors in the

system. A new chemical plant in South America is presently system. Each governor will respond to this input signal as re-

designing a DCS system that will control all critical system quired to meet all of the control objectives of the governor

functions: system.

Mechanical-hydraulic extraction or admission systems need

- Turbine speed control a significant amount of adjustment and maintenance, due to the

- Process control high amount of friction in the system. Please refer to

- Surge protection Figure 5.11.12, which shows a mechanical-hydraulic single ex-

- ESD systems traction governor system. As a result, all new systems

- On-line monitoring

- Emergency pump auto-start

In this design, all critical functions are actuated on the basis of

a two-out-of-three voting system.

As previously discussed, extraction turbines are used to op- Application-driven Speed Type of governor

timize plant steam balance and overall steam cycle efficiency. equipment regulation % system

Figure 5.11.11 defines the function of an extraction steam tur- Spared pump NEMA A + 10% Mechanical (older

bine control system. – applications)

Both mechanical-hydraulic and electro-hydraulic extraction Mechanical (hydraulic)

control systems are successfully operating in the field. Either Electro-hydraulic

design incorporates two or more governors operating together (optional)*

to meet the control system objectives. Each governor’s output Non-redundant

–

controls a specific set of throttle valves. In addition, each Fan(s) NEMA A + 10% Mechanical (older

hydraulics)

Mechanical hydraulic

Lube/seal oil pump(s) NEMA A + 10% Mechanical/hydraulic

–

Turbo-compressor NEMA D + – 0.5% Electro-hydraulic (post

Function: Continuously provide cool, clean control oil to control 1980)

and protection system at proper pressure, flow rate and Non-redundant

temperature. Optional-redundant,

Frequent problem areas: triple redundant

Main to auxiliary pump transfer Generator NEMA D + – 0.5% Isochronous (0% droop)

Control oil valve instability Mechanical/hydraulic

Instantaneous flow requirement changes (need for Present

accumulator) Electro-hydraulic

Fig 5.11.14 Control oil system Fig 5.11.15 Steam turbine governor system application chart

293