Page 315 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 315

Be st Practice 5 .11 Steam Turbine Best Practices

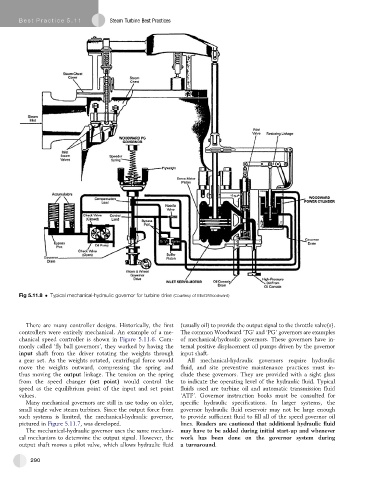

Fig 5.11.8 Typical mechanical-hydraulic governor for turbine drive (Courtesy of Elliott/Woodward)

There are many controller designs. Historically, the first (usually oil) to provide the output signal to the throttle valve(s).

controllers were entirely mechanical. An example of a me- The common Woodward ‘TG’ and ‘PG’ governors are examples

chanical speed controller is shown in Figure 5.11.6.Com- of mechanical/hydraulic governors. These governors have in-

monly called ‘flyball governors’, they worked by having the ternal positive displacement oil pumps driven by the governor

input shaft from the driver rotating the weights through input shaft.

a gear set. As the weights rotated, centrifugal force would All mechanical-hydraulic governors require hydraulic

move the weights outward, compressing the spring and fluid, and site preventive maintenance practices must in-

thus moving the output linkage. The tension on the spring clude these governors. They are provided with a sight glass

from the speed changer (set point) would control the to indicate the operating level of the hydraulic fluid. Typical

speed as the equilibrium point of the input and set point fluids used are turbine oil and automatic transmission fluid

values. ‘ATF’. Governor instruction books must be consulted for

Many mechanical governors are still in use today on older, specifichydraulic specifications. In larger systems, the

small single valve steam turbines. Since the output force from governor hydraulic fluid reservoir may not be large enough

such systems is limited, the mechanical-hydraulic governor, to provide sufficient fluid to fill all of the speed governor oil

pictured in Figure 5.11.7, was developed. lines. Readers are cautioned that additional hydraulic fluid

The mechanical-hydraulic governor uses the same mechani- may have to be added during initial start-up and whenever

cal mechanism to determine the output signal. However, the work has been done on the governor system during

output shaft moves a pilot valve, which allows hydraulic fluid a turnaround.

290