Page 325 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 325

Be st Practice 5 .12 Steam Turbine Best Practices

- Manually pushing spring loaded handle

The protection system monitors steam turbine total train parameters - Solenoid valve opening

and ensures safety and reliability by the following action:

The solenoid valve will open on command when any trip

Start-up (optional) provides a safe, reliable fully automatic start-

up and will shut down the turbine on any abnormality parameter set point is exceeded. Solenoid valves are designed to

Manual shutdown be normally energized to close.

Trip valve exerciser allows trip valve stem movement to be In recent years the industry has required parallel and series

con firmed during operation without shutdown arrangements of solenoid valves to ensure increased steam tur-

Rotor overspeed monitors turbine rotor speed and will shut bine train reliability. Figure 5.12.3 shows two popular methods

down turbine when maximum allowable speed (trip speed) is

attained of overspeed protection used in the past.

Excessive process variable signal monitors all train process Today, most speed trip systems incorporate magnetic speed

variables and will shut down turbine when maximum value is input signals and two-out-of-three voting for increased re-

exceeded liability. Figure 5.12.4 presents the devices that trip the turbine

internally. That is, they directly reduce the control oil pressure

causing a trip valve closure without the need of a solenoid valve

Fig 5.12.1 Protection

(external trip method).

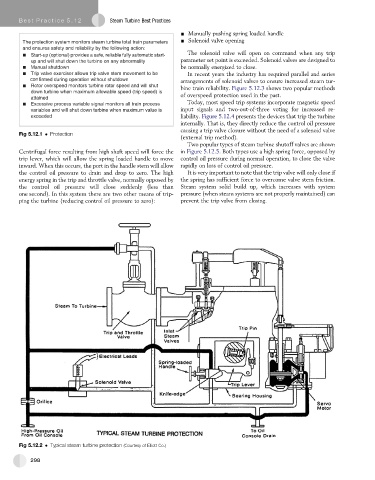

Two popular types of steam turbine shutoff valves are shown

Centrifugal force resulting from high shaft speed will force the in Figure 5.12.5. Both types use a high spring force, opposed by

trip lever, which will allow the spring loaded handle to move control oil pressure during normal operation, to close the valve

inward. When this occurs, the port in the handle stem will allow rapidly on loss of control oil pressure.

the control oil pressure to drain and drop to zero. The high It is very important to note that the trip valve will only close if

energy spring in the trip and throttle valve, normally opposed by the spring has sufficient force to overcome valve stem friction.

the control oil pressure will close suddenly (less than Steam system solid build up, which increases with system

one second). In this system there are two other means of trip- pressure (when steam systems are not properly maintained) can

ping the turbine (reducing control oil pressure to zero): prevent the trip valve from closing.

Fig 5.12.2 Typical steam turbine protection (Courtesy of Elliott Co.)

298