Page 350 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 350

Gas Turbine Best Practices Be st Practice 6.1

coupling environment is significantly reduced in terms of tem-

perature. This results in a much lower axial expansion of the

drive coupling and subsequently increases the reliability of the

gas turbine.

Gas turbine cycles

Gas turbine cycles are presented in Figure 6.1.21. There are

essentially three types of gas turbine cycles: first is the simple

cycle, where the gas is exhausted directly to atmosphere;

secondly, the regenerative cycle, where the exhaust gas is used

in an exchanger (regenerator) to preheat the compressor dis-

charge air prior to the combustor; and finally there is the

combined cycle, where the exhaust gas is used in a heat re-

covery steam generator (HRSG) to either generate steam for

plant use or as an expansion fluid is a steam turbine. Typical

efficiencies are as follows:

- Simple cycle 20% to 43%

- Regenerative cycle 30% to 45%

- Combined cycle 55% to 60%

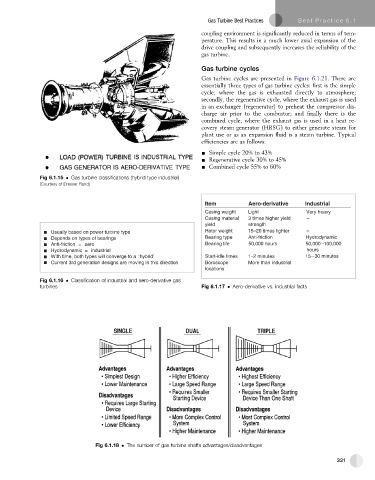

Fig 6.1.15 Gas turbine classifications (hybrid type industrial)

(Courtesy of Dresser Rand)

Item Aero-derivative Industrial

Casing weight Light Very heavy

Casing material 3 times higher yield –

yield strength

Usually based on power turbine type Rotor weight 15–20 times lighter –

Depends on types of bearings Bearing type Anti-friction Hydrodynamic

Anti-friction = aero Bearing life 50,000 hours 50,000–100,000

Hydrodynamic = industrial hours

With time, both types will converge to a ‘hybrid’ Start-idle times 1–2 minutes 15–30 minutes

Current 3rd generation designs are moving in this direction Boroscope More than industrial

locations

Fig 6.1.16 Classification of industrial and aero-derivative gas

turbines Fig 6.1.17 Aero-derivative vs. industrial facts

Fig 6.1.18 The number of gas turbine shafts advantages/disadvantages

321