Page 543 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 543

Be st Practice 9 .3 Dry Gas Seal Best Practices

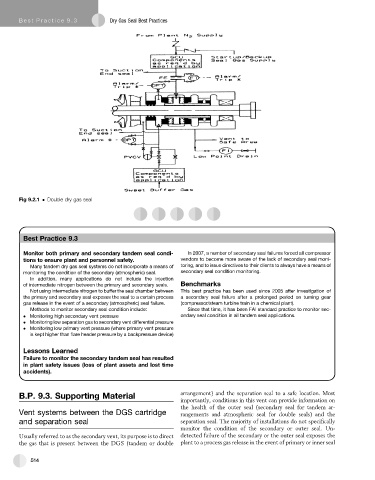

Fig 9.2.1 Double dry gas seal

Best

Best

Best Practice 9.3Practice 9.3Practice 9.3

Monitor both primary and secondary tandem seal condi- In 2007, a number of secondary seal failures forced all compressor

tions to ensure plant and personnel safety. vendors to become more aware of the lack of secondary seal moni-

Many tandem dry gas seal systems do not incorporate a means of toring, and to issue directives to their clients to always have a means of

monitoring the condition of the secondary (atmospheric) seal. secondary seal condition monitoring.

In addition, many applications do not include the injection

of intermediate nitrogen between the primary and secondary seals. Benchmarks

Not using intermediate nitrogen to buffer the seal chamber between This best practice has been used since 2005 after investigation of

the primary and secondary seal exposes the seal to a certain process a secondary seal failure after a prolonged period on turning gear

gas release in the event of a secondary (atmospheric) seal failure. (compressor/steam turbine train in a chemical plant).

Methods to monitor secondary seal condition include: Since that time, it has been FAI standard practice to monitor sec-

Monitoring high secondary vent pressure ondary seal condition in all tandem seal applications.

Monitoring low separation gas to secondary vent differential pressure

Monitoring low primary vent pressure (where primary vent pressure

is kept higher than flare header pressure by a backpressure device)

Lessons Learned

Failure to monitor the secondary tandem seal has resulted

in plant safety issues (loss of plant assets and lost time

accidents).

B.P. 9.3. Supporting Material arrangement) and the separation seal to a safe location. Most

importantly, conditions in this vent can provide information on

the health of the outer seal (secondary seal for tandem ar-

Vent systems between the DGS cartridge rangements and atmospheric seal for double seals) and the

and separation seal separation seal. The majority of installations do not specifically

monitor the condition of the secondary or outer seal. Un-

Usually referred to as the secondary vent, its purpose is to direct detected failure of the secondary or the outer seal exposes the

the gas that is present between the DGS (tandem or double plant to a process gas release in the event of primary or inner seal

514