Page 585 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 585

Be st Practice 1 0.12 The Post-Shipment Phase: Installation, Pre-Commissioning, Commissioning and Start-up Best Practices

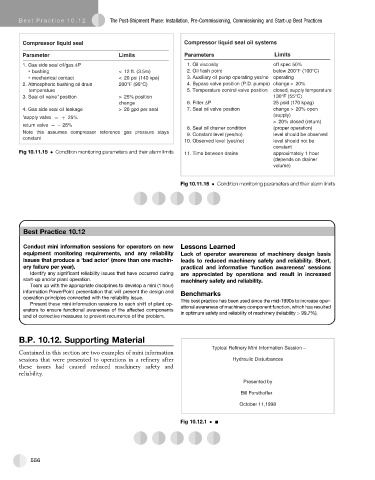

Compressor liquid seal Compressor liquid seal oil systems

Parameter Limits Parameters Limits

1. Gas side seal oil/gas P . 1 l i O s i v c o y t i s f f o s p e c 5 0 %

bushing < 12 ft. (3.5m) 2. Oil fl sa h p t n i o b o l e w 2 0 0°F (100°C)

mechanical contact < 20 psi (140 kpa) 3. Auxiliary oil pump operating yes/no operating

2. Atmospheric bushing oil drain 200°F (95°C) 4. Bypass valve position (P.D. pumps) change > 20%

temperature 5. Temperature control valve position closed, supply temperature

3. Seal oil valve position > 25% position 130°F (55°C)

change 6. Filter P 2 5 p d i s 1 ( 7 0 k p a ) g

4. Gas side seal oil leakage > 20 gpd per seal 7. Seal oil valve position change > 20% open

(supply)

supply valve 25%

> 20% closed (return)

return valve 25%

8. Seal oil drainer condition (proper operation)

Note this assumes compressor reference gas pressure stays 9. Constant level (yes/no) level should be observed

constant

10. Observed level (yes/no) level should not be

constant

Fig 10.11.15 Condition monitoring parameters and their alarm limits 11. Time between drains approximately 1 hour

(depends on drainer

volume)

Fig 10.11.16 Condition monitoring parameters and their alarm limits

Best Practice 10.12

Conduct mini information sessions for operators on new Lessons Learned

equipment monitoring requirements, and any reliability Lack of operator awareness of machinery design basis

issues that produce a ‘bad actor’ (more than one machin- leads to reduced machinery safety and reliability. Short,

ery failure per year). practical and informative ‘function awareness’ sessions

Identify any significant reliability issues that have occurred during are appreciated by operations and result in increased

start-up and/or plant operation. machinery safety and reliability.

Team up with the appropriate disciplines to develop a mini (1 hour)

information PowerPoint presentation that will present the design and Benchmarks

operation principles connected with the reliability issue. This best practice has been used since the mid-1990s to increase oper-

Present these mini information sessions to each shift of plant op-

erators to ensure functional awareness of the affected components ational awareness of machinery component function, which has resulted

in optimum safety and reliability of machinery (reliability > 99.7%).

and of corrective measures to prevent recurrence of the problem.

B.P. 10.12. Supporting Material

Typical Refinery Mini Information Session –

Contained in this section are two examples of mini information

sessions that were presented to operations in a refinery after Hydraulic Disturbances

these issues had caused reduced machinery safety and

reliability.

Presented by

Bill Forsthoffer

October 11,1998

Fig 10.12.1 -

556