Page 88 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 88

Be st Practice 2 .12 Pump Best Practices

Internal inlet pressure losses Cavitation is the result of released energy when an increase of

Formation of low pressure cells at low flows pressure surrounding the fluid causes the saturated vapor to change

Liquid temperature rise at low flows back to a liquid

Fig 2.12.12 Causes of vaporization within a centrifugal pump Fig 2.12.13 Cavitation definition

When operating at low flows, the efficiency of the impeller is

significantly reduced, thus increasing the liquid temperature rise. This indicates that vapor must be present before cavitation

As previously mentioned, the vapor pressure of any liquid in- can take place. The sources of vapor formation were discussed

creases with temperature. Increased temperature can cause the and are summarized in Figure 2.12.12. Referring back to

liquid to vaporize at the impeller vanes. Referring to Figure 2.12.8, it can be seen that as soon as the liquid enters the

impeller vane area, its energy and pressure rapidly increase.

Figure 2.12.12, it can be seen that low specific gravity liquids with

high vapor pressures are the most susceptible to vaporization When its pressure liquid exceeds the vapor pressure, the vapor

bubbles will collapse and cavitation will occur. Ways to prevent

caused by low flow operation. Note that increased wear ring

clearances can worsen this situation, since the higher temperature cavitation are shown in Figure 2.12.14. They will be discussed in

liquid will mix with the cooler liquid entering the impeller. more details later on in this chapter.

Figure 2.12.12 summarizes the causes of vaporization within a

centrifugal pump.

Cavitation is prevented by preventing vapor formation within a pump

Causes of damage

Fig 2.12.14 Preventing cavitation

In the above section the causes of vapor formation within

a pump were described. In this section the causes of damage to

pump components will be discussed. The effects of fluids on component damage

The energy released during cavitation caused by inlet pressure

Cavitation losses, recirculation or low flow temperature rise varies as

a function of the fluid type and the amount of vaporization. In

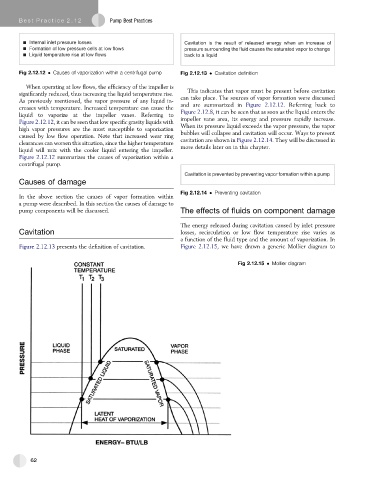

Figure 2.12.13 presents the definition of cavitation. Figure 2.12.15, we have drawn a generic Mollier diagram to

Fig 2.12.15 Mollier diagram

62