Page 95 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 95

Pump Best Practices Best Practice 2 .13

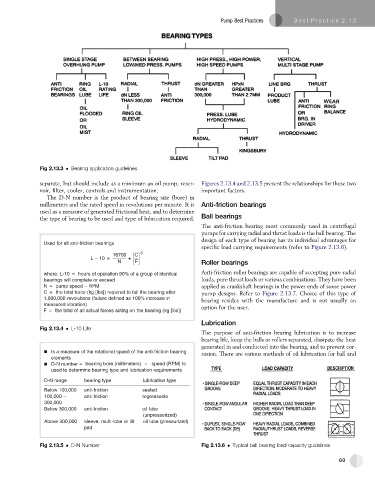

Fig 2.13.3 Bearing application guidelines

separate, but should include as a minimum an oil pump, reser- Figures 2.13.4 and 2.13.5 present the relationships for these two

voir, filter, cooler, controls and instrumentation. important factors.

The D-N number is the product of bearing size (bore) in

millimeters and the rated speed in revolutions per minute. It is Anti-friction bearings

used as a measure of generated frictional heat, and to determine

the type of bearing to be used and type of lubrication required. Ball bearings

The anti-friction bearing most commonly used in centrifugal

pumps for carrying radial and thrust loads is the ball bearing. The

design of each type of bearing has its individual advantages for

Used for all anti-friction bearings

specific load carrying requirements (refer to Figure 2.13.6).

16700 C 3

L 10 =

N F Roller bearings

where: L-10 = hours of operation 90% of a group of identical Anti-friction roller bearings are capable of accepting pure radial

bearings will complete or exceed loads, pure thrust loads or various combinations. They have been

N = pump speed – RPM applied as crankshaft bearings in the power ends of some power

C = the total force (kg [lbs]) required to fail the bearing after pump designs. Refer to Figure 2.13.7. Choice of this type of

1,000,000 revolutions (failure defined as 100% increase in bearing resides with the manufacture and is not usually an

measured vibration) option for the user.

F = the total of all actual forces acting on the bearing (kg [lbs])

Lubrication

Fig 2.13.4 L-10 Life

The purpose of anti-friction bearing lubrication is to increase

bearing life, keep the balls or rollers separated, dissipate the heat

generated in and conducted into the bearing, and to prevent cor-

Is a measure of the rotational speed of the anti-friction bearing rosion. There are various methods of oil lubrication for ball and

elements

D-N number = bearing bore (millimeters) speed (RPM) Is

used to determine bearing type and lubrication requirements

D-N range bearing type lubrication type

Below 100,000 anti-friction sealed

100,000 – anti-friction regreasable

300,000

Below 300,000 anti-friction oil lube

(unpressurized)

Above 300,000 sleeve, multi-lobe or tilt oil lube (pressurized)

pad

Fig 2.13.5 D-N Number Fig 2.13.6 Typical ball bearing load capacity guidelines

69