Page 100 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 100

Be st Practice 2 .17 Pump Best Practices

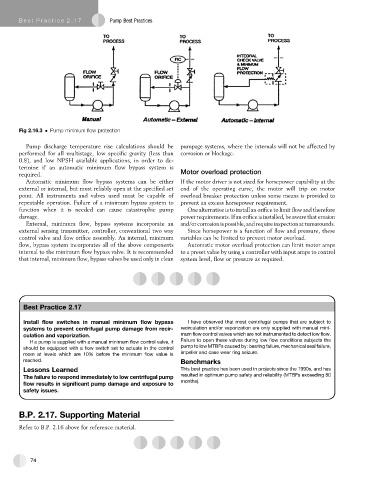

Fig 2.16.3 Pump minimum flow protection

Pump discharge temperature rise calculations should be pumpage systems, where the internals will not be affected by

performed for all multistage, low specificgravity (lessthan corrosion or blockage.

0.8), and low NPSH available applications, in order to de-

termine if an automatic minimum flow bypass system is

required. Motor overload protection

Automatic minimum flow bypass systems can be either If the motor driver is not sized for horsepower capability at the

external or internal, but must reliably open at the specified set end of the operating curve, the motor will trip on motor

point. All instruments and valves used must be capable of overload breaker protection unless some means is provided to

repeatable operation. Failure of a minimum bypass system to prevent an excess horsepower requirement.

function when it is needed can cause catastrophic pump One alternative is to install an orifice to limit flow and therefore

damage. power requirements. If an orifice is installed, be aware that erosion

External, minimum flow, bypass systems incorporate an and/orcorrosionispossible,andrequire inspection at turnarounds.

external sensing transmitter, controller, conventional two way Since horsepower is a function of flow and pressure, these

control valve and flow orifice assembly. An internal, minimum variables can be limited to prevent motor overload.

flow, bypass system incorporates all of the above components Automatic motor overload protection can limit motor amps

internal to the minimum flow bypass valve. It is recommended to a preset value by using a controller with input amps to control

that internal, minimum flow, bypass valves be used only in clean system level, flow or pressure as required.

Best Practice 2.17Practice 2.17

Best

Install flow switches in manual minimum flow bypass I have observed that most centrifugal pumps that are subject to

systems to prevent centrifugal pump damage from recir- recirculation and/or vaporization are only supplied with manual mini-

culation and vaporization. mum flow control valves which are not instrumented to detect low flow.

If a pump is supplied with a manual minimum flow control valve, it Failure to open these valves during low flow conditions subjects the

should be equipped with a flow switch set to actuate in the control pump to low MTBFs caused by: bearing failure, mechanical seal failure,

room at levels which are 10% before the minimum flow value is impeller and case wear ring seizure.

reached. Benchmarks

Lessons Learned This best practice has been used in projects since the 1990s, and has

The failure to respond immediately to low centrifugal pump resulted in optimum pump safety and reliability (MTBFs exceeding 80

months).

flow results in significant pump damage and exposure to

safety issues.

B.P. 2.17. Supporting Material

Refer to B.P. 2.16 above for reference material.

74