Page 96 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 96

Be st Practice 2 .13 Pump Best Practices

Fig 2.13.7 Anti-friction roller bearings (Courtesy of Union Pump Co.)

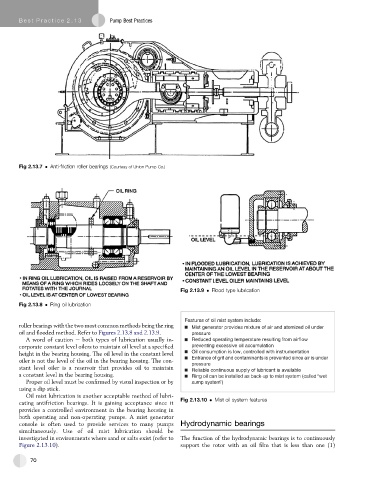

Fig 2.13.9 Flood type lubrication

Fig 2.13.8 Ring oil lubrication

Features of oil mist system include:

roller bearings with the two most common methods being the ring Mist generator provides mixture of air and atomized oil under

oil and flooded method. Refer to Figures 2.13.8 and 2.13.9. pressure

A word of caution e both types of lubrication usually in- Reduced operating temperature resulting from airflow

corporate constant level oilers to maintain oil level at a specified preventing excessive oil accumulation

height in the bearing housing. The oil level in the constant level Oil consumption is low, controlled with instrumentation

oiler is not the level of the oil in the bearing housing. The con- Entrance of grit and contaminants is prevented since air is under

pressure

stant level oiler is a reservoir that provides oil to maintain

Reliable continuous supply of lubricant is available

a constant level in the bearing housing. Ring oil can be installed as back-up to mist system (called “wet

Proper oil level must be confirmed by visual inspection or by sump system”)

using a dip stick.

Oil mist lubrication is another acceptable method of lubri-

cating antifriction bearings. It is gaining acceptance since it Fig 2.13.10 Mist oil system features

provides a controlled environment in the bearing housing in

both operating and non-operating pumps. A mist generator

console is often used to provide services to many pumps Hydrodynamic bearings

simultaneously. Use of oil mist lubrication should be

investigated in environments where sand or salts exist (refer to The function of the hydrodynamic bearings is to continuously

Figure 2.13.10). support the rotor with an oil film that is less than one (1)

70