Page 292 - Fundamentals of The Finite Element Method for Heat and Fluid Flow

P. 292

SOME EXAMPLES OF FLUID FLOW AND HEAT TRANSFER PROBLEMS

284

the chip (location of the maximum temperature) and the ambient, referred to as R ja and

defined as

T j − T a

R ja = (9.1)

P

where T j is the chip temperature, T a is the ambient temperature and P is the power

dissipated by the chip.

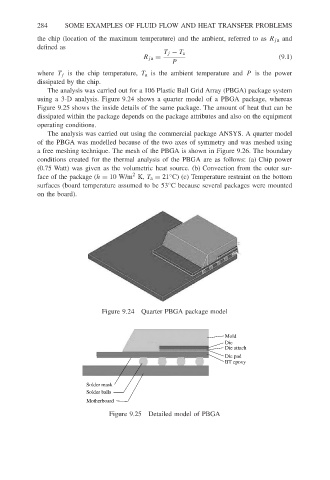

The analysis was carried out for a 106 Plastic Ball Grid Array (PBGA) package system

using a 3-D analysis. Figure 9.24 shows a quarter model of a PBGA package, whereas

Figure 9.25 shows the inside details of the same package. The amount of heat that can be

dissipated within the package depends on the package attributes and also on the equipment

operating conditions.

The analysis was carried out using the commercial package ANSYS. A quarter model

of the PBGA was modelled because of the two axes of symmetry and was meshed using

a free meshing technique. The mesh of the PBGA is shown in Figure 9.26. The boundary

conditions created for the thermal analysis of the PBGA are as follows: (a) Chip power

(0.75 Watt) was given as the volumetric heat source. (b) Convection from the outer sur-

2

face of the package (h = 10 W/m K, T a = 21 C) (c) Temperature restraint on the bottom

◦

surfaces (board temperature assumed to be 53 C because several packages were mounted

◦

on the board).

Figure 9.24 Quarter PBGA package model

Mold

Die

Die attach

Die pad

BT epoxy

Solder mask

Solder balls

Motherboard

Figure 9.25 Detailed model of PBGA