Page 260 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 260

Coagulation 215

1.0

• Base exchange capacity of clay= 31.4 μm/L Motor

• Clay concentration=286 mg/L

0.5

Shaft guide

0.0 Cylinder

Mobility (μm/s/V/cm) –0.5 Sample in Sample out

–1.0

–1.5

–2.0 Electrode

Piston

–2.5

–3.0

0 10 20 30 40 50 60 70 80 90 100

Alum dosage (mg/L)

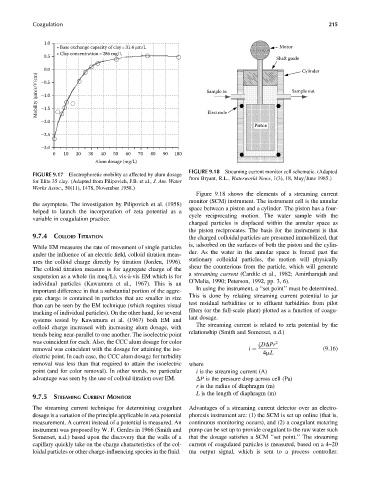

FIGURE 9.18 Streaming current monitor cell schematic. (Adapted

FIGURE 9.17 Electrophoretic mobility as affected by alum dosage

for Illite 35 clay. (Adapted from Pilipovich, J.B. et al., J. Am. Water from Bryant, R.L., Waterworld News, 1(3), 18, May=June 1985.)

Works Assoc., 50(11), 1478, November 1958.)

Figure 9.18 shows the elements of a streaming current

monitor (SCM) instrument. The instrument cell is the annular

the asymptote. The investigation by Pilipovich et al. (1958)

space between a piston and a cylinder. The piston has a four-

helped to launch the incorporation of zeta potential as a

cycle reciprocating motion. The water sample with the

variable in coagulation practice.

charged particles is displaced within the annular space as

the piston reciprocates. The basis for the instrument is that

9.7.4 COLLOID TITRATION the charged colloidal particles are presumed immobilized, that

is, adsorbed on the surfaces of both the piston and the cylin-

While EM measures the rate of movement of single particles

der. As the water in the annular space is forced past the

under the influence of an electric field, colloid titration meas-

stationary colloidal particles, the motion will physically

ures the colloid charge directly by titration (Jorden, 1996).

shear the counterions from the particle, which will generate

The colloid titration measure is for aggregate charge of the

a streaming current (Cardile et al., 1982; Amirtharajah and

suspension as a whole (in meq=L), vis-à-vis EM which is for

O’Melia, 1990; Peterson, 1992, pp. 3, 6).

individual particles (Kawamura et al., 1967). This is an

In using the instrument, a ‘‘set point’’ must be determined.

important difference in that a substantial portion of the aggre-

This is done by relating streaming current potential to jar

gate charge is contained in particles that are smaller in size

test residual turbidities or to effluent turbidities from pilot

than can be seen by the EM technique (which requires visual

filters (or the full-scale plant) plotted as a function of coagu-

tracking of individual particles). On the other hand, for several

lant dosage.

systems tested by Kawamura et al. (1967) both EM and

The streaming current is related to zeta potential by the

colloid charge increased with increasing alum dosage, with

relationship (Smith and Somerset, n.d.)

trends being near-parallel to one another. The isoelectric point

was coincident for each. Also, the CCC alum dosage for color 2

zDDPr

removal was coincident with the dosage for attaining the iso- i ¼ (9:16)

4mL

electric point. In each case, the CCC alum dosage for turbidity

removal was less than that required to attain the isoelectric where

point (and for color removal). In other words, no particular i is the streaming current (A)

advantage was seen by the use of colloid titration over EM. DP is the pressure drop across cell (Pa)

r is the radius of diaphragm (m)

L is the length of diaphragm (m)

9.7.5 STREAMING CURRENT MONITOR

The streaming current technique for determining coagulant Advantages of a streaming current detector over an electro-

dosage is a variation of the principle applicable in zeta potential phoresis instrument are: (1) the SCM is set up online (that is,

measurement. A current instead of a potential is measured. An continuous monitoring occurs), and (2) a coagulant metering

instrument was proposed by W. F. Gerdes in 1966 (Smith and pump can be set up to provide coagulant to the raw water such

Somerset, n.d.) based upon the discovery that the walls of a that the dosage satisfies a SCM ‘‘set point.’’ The streaming

capillary quickly take on the charge characteristics of the col- current of coagulated particles is measured, based on a 4–20

loidal particles or other charge-influencing species in the fluid. ma output signal, which is sent to a process controller.