Page 375 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 375

330 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

wash and=or an air scour; one or both is essential to cleaning

Filter tank

Wash troughs the media adequately. The wastewater from the backwash is

removed by overflow launders, that is, troughs. After the

backwash is completed, the filtration cycle is started again.

Provision for filter-to-waste is recommended, which may be

Filter used during the filter ‘‘ripening,’’ that is, at the start of the

media filter run.

The system also includes provision for treated water stor-

age, both to provide detention time for disinfection and to

account for diurnal fluctuation in demand, and perhaps help

Graded meet days of peak demand. Backwash water may be stored

gravel

separately and elevated, which avoids the risk of a cross

connection with treated water storage. The wastewater is

Perforated laterals

conveyed to a solids storage pond where the decanted water

Filter floor

is returned to the head of the plant.

Cast-iron manifold

12.1.1.3 Filtration Mode

The particular process steps prior to depth filtration, determine

the ‘‘mode’’ of filtration, that is, inline, direct, or conventional,

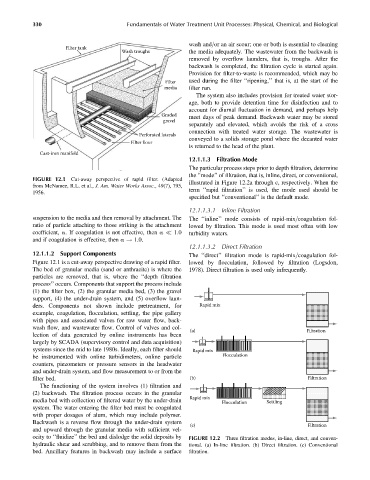

FIGURE 12.1 Cut-away perspective of rapid filter. (Adapted

illustrated in Figure 12.2a through c, respectively. When the

from McNamee, R.L. et al., J. Am. Water Works Assoc., 49(7), 795,

term ‘‘rapid filtration’’ is used, the mode used should be

1956.

specified but ‘‘conventional’’ is the default mode.

12.1.1.3.1 Inline Filtration

suspension to the media and then removal by attachment. The The ‘‘inline’’ mode consists of rapid-mix=coagulation fol-

ratio of particle attaching to those striking is the attachment lowed by filtration. This mode is used most often with low

coefficient, a. If coagulation is not effective, then a 1.0 turbidity waters.

and if coagulation is effective, then a ! 1.0.

12.1.1.3.2 Direct Filtration

12.1.1.2 Support Components The ‘‘direct’’ filtration mode is rapid-mix=coagulation fol-

Figure 12.1 is a cut-away perspective drawing of a rapid filter. lowed by flocculation, followed by filtration (Logsdon,

The bed of granular media (sand or anthracite) is where the 1978). Direct filtration is used only infrequently.

particles are removed, that is, where the ‘‘depth filtration

process’’ occurs. Components that support the process include

(1) the filter box, (2) the granular media bed, (3) the gravel

support, (4) the under-drain system, and (5) overflow laun-

ders. Components not shown include pretreatment, for Rapid mix

example, coagulation, flocculation, settling, the pipe gallery

with pipes and associated valves for raw water flow, back-

wash flow, and wastewater flow. Control of valves and col-

(a) Filtration

lection of data generated by online instruments has been

largely by SCADA (supervisory control and data acquisition)

systems since the mid to late 1980s. Ideally, each filter should Rapid mix

be instrumented with online turbidimeters, online particle Flocculation

counters, piezometers or pressure sensors in the headwater

and under-drain system, and flow measurement to or from the

filter bed. (b) Filtration

The functioning of the system involves (1) filtration and

(2) backwash. The filtration process occurs in the granular

Rapid mix

media bed with collection of filtered water by the under-drain Flocculation Settling

system. The water entering the filter bed must be coagulated

with proper dosages of alum, which may include polymer.

Backwash is a reverse flow through the under-drain system

(c) Filtration

and upward through the granular media with sufficient vel-

ocity to ‘‘fluidize’’ the bed and dislodge the solid deposits by FIGURE 12.2 Three filtration modes, in-line, direct, and conven-

hydraulic shear and scrubbing, and to remove them from the tional. (a) In-line filtration. (b) Direct filtration. (c) Conventional

bed. Ancillary features in backwash may include a surface filtration.