Page 20 - Gas Purification 5E

P. 20

10 Gas Purification

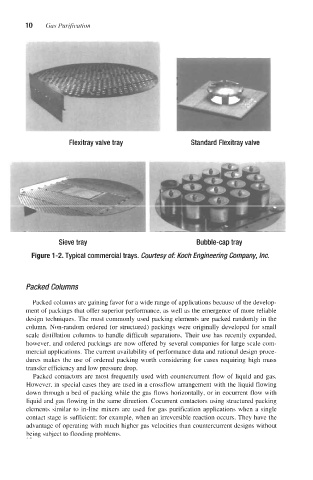

Flexitray valve tray Standard Flexitray valve

Sieve tray Bubble-cap tray

Figure 1-2. Typical commercial trays. Courtesy of: Koch Engineering Company, Inc.

Packed Columns

Packed columns are gaining favor for a wide range of applications because of the develop-

ment of packings that offer superior performance, as well as the emergence of more reliable

design techniques. The most commonly used packing elements are packed randomly in the

column. Non-random ordered (or structured) packings were originally developed for small

scale distillation columns to handle difficult separations. Their use has recently expanded,

however, and ordered packings are now offered by several companies for large scale com-

mercial applications. The current availability of performance data and rational design proce-

dures makes the use of ordered packing worth considering for cases requiring high mass

transfer efficiency and low pressure drop.

Packed contactors are most frequently used with countercurrent flow of liquid and gas.

However, in special cases they are used in a crossflow arrangement with the liquid flowing

down through a bed of packing while the gas flows horizontally, or in cocurrent flow with

liquid and gas flowing in the same direction. Cocurrent contactors using structured packing

elements similar to in-line mixers are used for gas purification applications when a single

contact stage is sufficient; for example, when an irreversible reaction occurs. They have the

advantage of operating with much higher gas velocities than countercurrent designs without

being subject to flooding problems.