Page 23 - Gas Purification 5E

P. 23

Introduction 13

O’Connell’s overall tray efficiency correlation (1946), Fair’s flooding correlation for sieve

tray columns (1961), Hughmark and O’Connell’s correlation relating to pressure drop of gas

through a dry tray (1957), Fair’s correlation for tray weeping (1963), and Eckert’s correlation

for flooding in a packed tower (1970A).

A number of commercially available software programs that include absorber design rou-

tines are listed in the CEP 1997 Software Directoly (Chem. Eng. Prog., 1997). A packed

tower design program for personal computers, which includes correlations for predicting the

efficiency and capacity of high efficiency structured packings, is described by Hausch and

Petschauer (1991). Detailed reviews of commonly used design procedures for absorption

operations are presented in several texts and articles including those of Edwards (1984), Fair

et al. (1984), Zenz (1979), Treybal (1980), Kohl (1987);and Diab and Maddox (1982). A

brief summary of the principal design equations and correlations is presented in the follow-

ing sections.

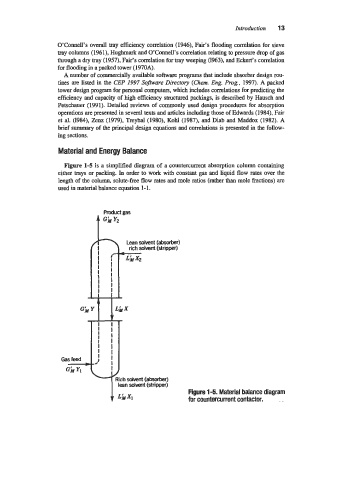

Material and Energy Balance

Figure 1-5 is a simplified diagram of a countercurrent absorption column containing

either trays or packing. In order to work with constant gas and liquid flow rates over the

length of the column, solute-free flow rates and mole ratios (rather than mole fractions) are

used in material balance equation 1-1.

Lean solvent (absorber)

rich solvent (stripper)

G; Y

Gas feed T ‘ I

1

Figure 1-5. Material balance diagram

for Countercurrent contactor.