Page 139 - Gas Wettability of Reservoir Rock Surfaces with Porous Media

P. 139

Effect of Gas Wettability on the Surface Properties CHAPTER 4 123

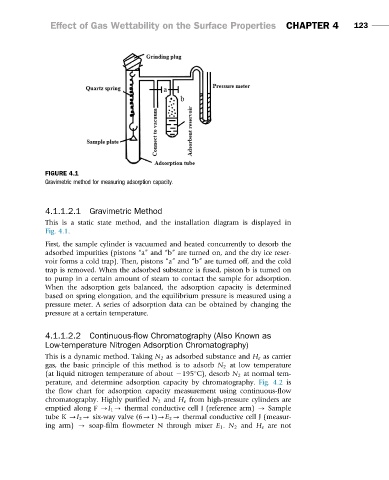

FIGURE 4.1

Gravimetric method for measuring adsorption capacity.

4.1.1.2.1 Gravimetric Method

This is a static state method, and the installation diagram is displayed in

Fig. 4.1.

First, the sample cylinder is vacuumed and heated concurrently to desorb the

adsorbed impurities (pistons “a” and “b” are turned on, and the dry ice reser-

voir forms a cold trap). Then, pistons “a” and “b” are turned off, and the cold

trap is removed. When the adsorbed substance is fused, piston b is turned on

to pump in a certain amount of steam to contact the sample for adsorption.

When the adsorption gets balanced, the adsorption capacity is determined

based on spring elongation, and the equilibrium pressure is measured using a

pressure meter. A series of adsorption data can be obtained by changing the

pressure at a certain temperature.

4.1.1.2.2 Continuous-flow Chromatography (Also Known as

Low-temperature Nitrogen Adsorption Chromatography)

This is a dynamic method. Taking N 2 as adsorbed substance and H e as carrier

gas, the basic principle of this method is to adsorb N 2 at low temperature

(at liquid nitrogen temperature of about 2195 C), desorb N 2 at normal tem-

perature, and determine adsorption capacity by chromatography. Fig. 4.2 is

the flow chart for adsorption capacity measurement using continuous-flow

chromatography. Highly purified N 2 and H e from high-pressure cylinders are

emptied along F -I 1 - thermal conductive cell J (reference arm) - Sample

tube K -I 2 - six-way valve ð6-1Þ-E 2 - thermal conductive cell J (measur-

ing arm) - soap-film flowmeter N through mixer E 1 . N 2 and H e are not