Page 245 - Gas Wettability of Reservoir Rock Surfaces with Porous Media

P. 245

Application of Gas Wettability CHAPTER 6 229

Table 6.18 Effect on the Experimental Well in Chunliang Oil Plant

Section Compared Injection Sandstone Effective Planned Actual Injection

Wells / Pressure Thickness Thickness Injection Injection Strength

3

Number (MPa) (m) (m) Volume Volume (m (d.

3

3

(m ) (m ) m) 21 )

Before 5 12.59 20.2 6.5 68 69 3.416

implementation

After 5 14.28 20.2 6.5 68 61 3.019

implementation

12

Daily injection volume under unit pressure (m 3 /MPa) 10 Plug removal Daily injection volume

8

Implementing trapezoid protection technology

6

4

2

0

0 2 4 6 8 10 12 14 16 18 20 22

Time, months

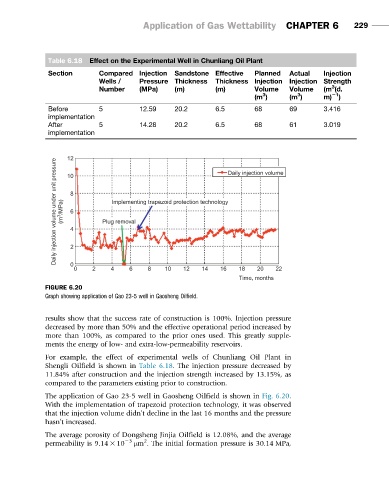

FIGURE 6.20

Graph showing application of Gao 23-5 well in Gaosheng Oilfield.

results show that the success rate of construction is 100%. Injection pressure

decreased by more than 50% and the effective operational period increased by

more than 100%, as compared to the prior ones used. This greatly supple-

ments the energy of low- and extra-low-permeability reservoirs.

For example, the effect of experimental wells of Chunliang Oil Plant in

Shengli Oilfield is shown in Table 6.18. The injection pressure decreased by

11.84% after construction and the injection strength increased by 13.15%, as

compared to the parameters existing prior to construction.

The application of Gao 23-5 well in Gaosheng Oilfield is shown in Fig. 6.20.

With the implementation of trapezoid protection technology, it was observed

that the injection volume didn’t decline in the last 16 months and the pressure

hasn’t increased.

The average porosity of Dongsheng Jinjia Oilfield is 12.08%, and the average

2

permeability is 9.14 3 10 23 μm . The initial formation pressure is 30.14 MPa,