Page 251 - Gas Wettability of Reservoir Rock Surfaces with Porous Media

P. 251

Application of Gas Wettability CHAPTER 6 235

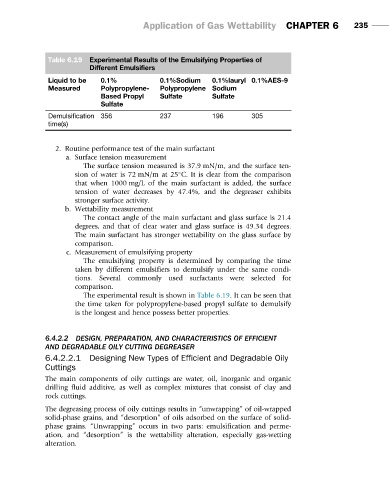

Table 6.19 Experimental Results of the Emulsifying Properties of

Different Emulsifiers

Liquid to be 0.1% 0.1%Sodium 0.1%lauryl 0.1%AES-9

Measured Polypropylene- Polypropylene Sodium

Based Propyl Sulfate Sulfate

Sulfate

Demulsification 356 237 196 305

time(s)

2. Routine performance test of the main surfactant

a. Surface tension measurement

The surface tension measured is 37.9 mN/m, and the surface ten-

sion of water is 72 mN/m at 25 C. It is clear from the comparison

that when 1000 mg/L of the main surfactant is added, the surface

tension of water decreases by 47.4%, and the degreaser exhibits

stronger surface activity.

b. Wettability measurement

The contact angle of the main surfactant and glass surface is 21.4

degrees, and that of clear water and glass surface is 49.34 degrees.

The main surfactant has stronger wettability on the glass surface by

comparison.

c. Measurement of emulsifying property

The emulsifying property is determined by comparing the time

taken by different emulsifiers to demulsify under the same condi-

tions. Several commonly used surfactants were selected for

comparison.

The experimental result is shown in Table 6.19. It can be seen that

the time taken for polypropylene-based propyl sulfate to demulsify

is the longest and hence possess better properties.

6.4.2.2 DESIGN, PREPARATION, AND CHARACTERISTICS OF EFFICIENT

AND DEGRADABLE OILY CUTTING DEGREASER

6.4.2.2.1 Designing New Types of Efficient and Degradable Oily

Cuttings

The main components of oily cuttings are water, oil, inorganic and organic

drilling fluid additive, as well as complex mixtures that consist of clay and

rock cuttings.

The degreasing process of oily cuttings results in “unwrapping” of oil-wrapped

solid-phase grains, and “desorption” of oils adsorbed on the surface of solid-

phase grains. “Unwrapping” occurs in two parts: emulsification and perme-

ation, and “desorption” is the wettability alteration, especially gas-wetting

alteration.