Page 182 - Geothermal Energy Renewable Energy and The Environment

P. 182

168 Geothermal Energy: Renewable Energy and the Environment

large pressure change. Realistically, under these operating conditions, m will be a small fraction

cw

of the 59.2 kg/s. For example, if complete evaporation of the cooling water were accomplished,

m would be approximately 3 kg/s. The actual value will depend on the operating conditions of

cw

the condenser, such as its pressure and the design temperature for the condensed water.

Following the condenser phase, the warm water from the condenser is cooled to the end state

condition by passage through a cooling tower. In the cooling tower the liquid water is sprayed into a

volume of moving air, allowing for evaporative cooling. In this process approximately half to three-

quarters of the mass of fluid supplied to the turbine is transferred to the atmosphere.

Regardless of the actual amount of water used in the condensing phase and during evaporative

cooling, this result is significant because it emphasizes the importance of treating water as an addi-

tional resource requiring careful management. This result also emphasizes that, in order to achieve

high efficiency in the generation process, a significant amount of cooling water is needed. We will

return to this point when we discuss the environmental issues associated with the utilization of

geothermal energy in Chapter 13.

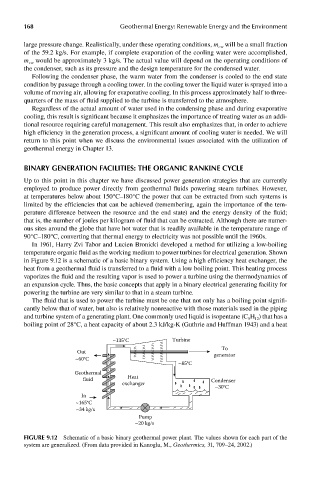

bInary GeneraTIon FacIlITIes: The orGanIc rankIne cycle

Up to this point in this chapter we have discussed power generation strategies that are currently

employed to produce power directly from geothermal fluids powering steam turbines. However,

at temperatures below about 150°C–180°C the power that can be extracted from such systems is

limited by the efficiencies that can be achieved (remembering, again the importance of the tem-

perature difference between the resource and the end state) and the energy density of the fluid;

that is, the number of joules per kilogram of fluid that can be extracted. Although there are numer-

ous sites around the globe that have hot water that is readily available in the temperature range of

90°C–180°C, converting that thermal energy to electricity was not possible until the 1960s.

In 1961, Harry Zvi Tabor and Lucien Bronicki developed a method for utilizing a low-boiling

temperature organic fluid as the working medium to power turbines for electrical generation. Shown

in Figure 9.12 is a schematic of a basic binary system. Using a high efficiency heat exchanger, the

heat from a geothermal fluid is transferred to a fluid with a low boiling point. This heating process

vaporizes the fluid and the resulting vapor is used to power a turbine using the thermodynamics of

an expansion cycle. Thus, the basic concepts that apply in a binary electrical generating facility for

powering the turbine are very similar to that in a steam turbine.

The fluid that is used to power the turbine must be one that not only has a boiling point signifi-

cantly below that of water, but also is relatively nonreactive with those materials used in the piping

and turbine system of a generating plant. One commonly used liquid is isopentane (C H ) that has a

5

12

boiling point of 28°C, a heat capacity of about 2.3 kJ/kg-K (Guthrie and Huffman 1943) and a heat

~135°C Turbine

To

Out generator

~60°C

~85°C

Geothermal

fluid Heat Condenser

exchanger

~30°C

In

~165°C

~34 kg/s

Pump

~20 kg/s

FIGUre 9.12 Schematic of a basic binary geothermal power plant. The values shown for each part of the

system are generalized. (From data provided in Kanoglu, M., Geothermics, 31, 709–24, 2002.)