Page 179 - Geothermal Energy Renewable Energy and The Environment

P. 179

Generating Power Using Geothermal Resources 165

sTeam qualiTy

One of the important factors influencing the performance of a generating system is the quality of

the steam that enters the turbine. Steam quality is defined as the proportion of water vapor to liq-

uid water in the steam phase. In Figure 9.7, the ratio of vapor-to-liquid in the two-phase region is

contoured by the dashed lines. As previously noted, Baumann (1921) found that every percentage

increase in moisture content of the vapor resulted in an approximately 0.5% drop in efficiency. This

raises an important consideration.

Remembering that our process is an idealized isenthalpic system, it is clear that we will maxi-

mize the amount of steam in our system if we reduce the temperature and pressure as much as possi-

ble. We will assume the final state will be 50°C (point 2 in Figure 9.7). For isentropic conditions, the

steam enthalpy would be 1980 kJ/kg and the realized enthalpy will be 2166 kJ/kg as before. From

mass balance relationships discussed earlier in Chapter 3, we find that about 33% of the fluid mass

is converted to steam (point 3 in Figure 9.7). Hence, for every kilogram of steam we must extract

three kilograms of liquid from the reservoir. Since each kilogram of liquid has an enthalpy of 1085

kJ/kg, we must extract 3245 kJ from the reservoir to obtain 638 kJ of work from the available steam.

As noted previously, moisture reduces turbine efficiency, and yet in this situation, two-thirds of the

mass of the system remains as liquid water. If this were to enter the turbine, the efficiency of our

energy extraction process would be diminished by about 30%, which would be an unacceptable loss

in generating capacity.

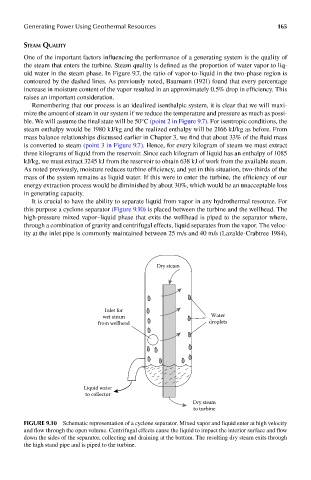

It is crucial to have the ability to separate liquid from vapor in any hydrothermal resource. For

this purpose a cyclone separator (Figure 9.10) is placed between the turbine and the wellhead. The

high-pressure mixed vapor–liquid phase that exits the wellhead is piped to the separator where,

through a combination of gravity and centrifugal effects, liquid separates from the vapor. The veloc-

ity at the inlet pipe is commonly maintained between 25 m/s and 40 m/s (Lazalde-Crabtree 1984),

Dry steam

Inlet for

wet steam Water

from wellhead droplets

Liquid water

to collector

Dry steam

to turbine

FIGUre 9.10 Schematic representation of a cyclone separator. Mixed vapor and liquid enter at high velocity

and flow through the open volume. Centrifugal effects cause the liquid to impact the interior surface and flow

down the sides of the separator, collecting and draining at the bottom. The resulting dry steam exits through

the high stand pipe and is piped to the turbine.