Page 193 - Geothermal Energy Renewable Energy and The Environment

P. 193

Generating Power Using Geothermal Resources 179

Technologies Program makes available a broad range of information relating to use, regula-

tions, standards and examples regarding geothermal energy and is an excellent resource.

sIdebar 9.1 Turbines

The most common means for producing electrical energy is through the use of a turbine to power an electrical gen-

erator. A turbine is a mechanical device that converts the energy of a fluid to mechanical rotational energy.

In the case of geothermal power production, the working fluid is steam. The turbine is used to convert the

enthalpy of the steam to useful power. The arrangements of the components of a basic steam turbine are shown in

Figures 9S.1 and 9S.2.

Energy conversion is accomplished by allowing high temperature and pressure geothermal steam to expand into

a region of lower temperature and pressure that is produced using a condenser and cooling system that cools the

steam. As the high P–T steam expands, it is directed to flow through a set of stationary blades (the stator) that focus

the fluid flow toward a set of blades mounted on a rotating shaft (the rotator). The energy of the fluid is partially con-

verted to rotational energy as the fluid moves over the rotating blades of the rotator. During this expansion process,

the fluid transfers its thermal enthalpy to kinetic energy of the rotating turbine shaft and the pressure and temperature

of the steam drop.

The efficiency of this process depends critically on the shape and dimensions of the blades. Since the enthalpy

content of the fluid is constantly dropping as it moves through the turbine, blade form and size must be different

along the length of the flow path in order to maximize energy transfer from the fluid to the shaft. Modern steam

turbines consist of a series of stator–rotator pairs arranged in stages that are designed specifically to extract, as effi-

ciently as possible, energy at different P–T conditions. The high-pressure stage usually has smaller diameter blade

High P–T

geothermal

Low P–T steam

geothermal

steam to

condenser

Turbine

rotator

Rotating

shaft

to electrical

generator

Low P–T

geothermal

steam to

condenser High P–T

geothermal

steam

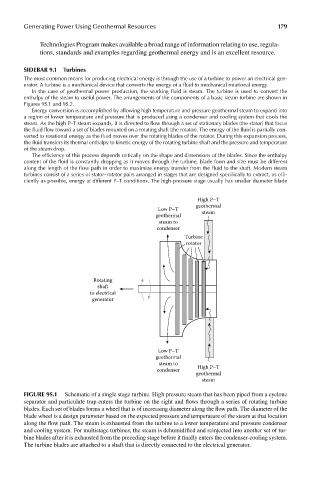

FIGUre 9s.1 Schematic of a single stage turbine. High pressure steam that has been piped from a cyclone

separator and particulate trap enters the turbine on the right and flows through a series of rotating turbine

blades. Each set of blades forms a wheel that is of increasing diameter along the flow path. The diameter of the

blade wheel is a design parameter based on the expected pressure and temperature of the steam at that location

along the flow path. The steam is exhausted from the turbine to a lower temperature and pressure condenser

and cooling system. For multistage turbines, the steam is dehumidified and reinjected into another set of tur-

bine blades after it is exhausted from the preceding stage before it finally enters the condenser-cooling system.

The turbine blades are attached to a shaft that is directly connected to the electrical generator.