Page 64 - Hacking Roomba

P. 64

Chapter 3 — Building a Roomba Serial Interface Tether 45

RS-232 transceiver s sub-circuit

VCC VCC

IC1 1µF

C5 1

C1+ 16 VCC

V+ 2 C1

1µF 3

C1- IC1P

V– 6

4 1µF GND

C6 C2+ 15

5 C7

1µF C2-

mini-din 8pin

8 11 T1IN T1OUT 14

7 GND 10 T2IN T2OUT 7 GND GND X1

6 DD 12 R1OUT R1IN 13 1

5 TXD 9 R2OUT R2IN 8 2 6

4 3 7

3 RXD MAX232 4 8

2 5 9

1

X2 VCC DB-9 female cable

+16VDC

IN OUT

C3 GND C2 LED1 green

IC2

1µF 78L05 1µF

220' R1

GND GND

voltage regulator LED

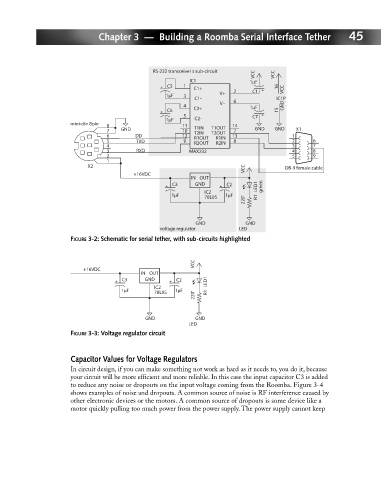

FIGURE 3-2: Schematic for serial tether, with sub-circuits highlighted

VCC

+16VDC

IN OUT

C3 GND C2 LED1

IC2

1µF 78L05 1µF

220' R1

GND GND

LED

FIGURE 3-3: Voltage regulator circuit

Capacitor Values for Voltage Regulators

In circuit design, if you can make something not work as hard as it needs to, you do it, because

your circuit will be more efficient and more reliable. In this case the input capacitor C3 is added

to reduce any noise or dropouts on the input voltage coming from the Roomba. Figure 3-4

shows examples of noise and dropouts. A common source of noise is RF interference caused by

other electronic devices or the motors. A common source of dropouts is some device like a

motor quickly pulling too much power from the power supply. The power supply cannot keep