Page 238 - Handbook Of Multiphase Flow Assurance

P. 238

Hydrate stability and crystal growth 237

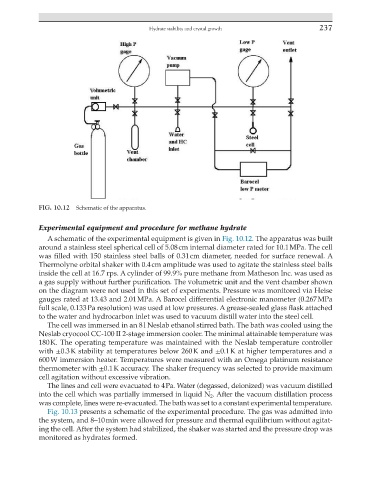

FIG. 10.12 Schematic of the apparatus.

Experimental equipment and procedure for methane hydrate

A schematic of the experimental equipment is given in Fig. 10.12. The apparatus was built

around a stainless steel spherical cell of 5.08 cm internal diameter rated for 10.1 MPa. The cell

was filled with 150 stainless steel balls of 0.31 cm diameter, needed for surface renewal. A

Thermolyne orbital shaker with 0.4 cm amplitude was used to agitate the stainless steel balls

inside the cell at 16.7 rps. A cylinder of 99.9% pure methane from Matheson Inc. was used as

a gas supply without further purification. The volumetric unit and the vent chamber shown

on the diagram were not used in this set of experiments. Pressure was monitored via Heise

gauges rated at 13.43 and 2.01 MPa. A Barocel differential electronic manometer (0.267 MPa

full scale, 0.133 Pa resolution) was used at low pressures. A grease-sealed glass flask attached

to the water and hydrocarbon inlet was used to vacuum distill water into the steel cell.

The cell was immersed in an 8 l Neslab ethanol stirred bath. The bath was cooled using the

Neslab cryocool CC-100 II 2-stage immersion cooler. The minimal attainable temperature was

180 K. The operating temperature was maintained with the Neslab temperature controller

with ±0.3 K stability at temperatures below 260 K and ±0.1 K at higher temperatures and a

600 W immersion heater. Temperatures were measured with an Omega platinum resistance

thermometer with ±0.1 K accuracy. The shaker frequency was selected to provide maximum

cell agitation without excessive vibration.

The lines and cell were evacuated to 4 Pa. Water (degassed, deionized) was vacuum distilled

into the cell which was partially immersed in liquid N 2 . After the vacuum distillation process

was complete, lines were re-evacuated. The bath was set to a constant experimental temperature.

Fig. 10.13 presents a schematic of the experimental procedure. The gas was admitted into

the system, and 8–10 min were allowed for pressure and thermal equilibrium without agitat-

ing the cell. After the system had stabilized, the shaker was started and the pressure drop was

monitored as hydrates formed.