Page 87 - Handbook Of Multiphase Flow Assurance

P. 87

82 4. Hydraulic and thermal analysis

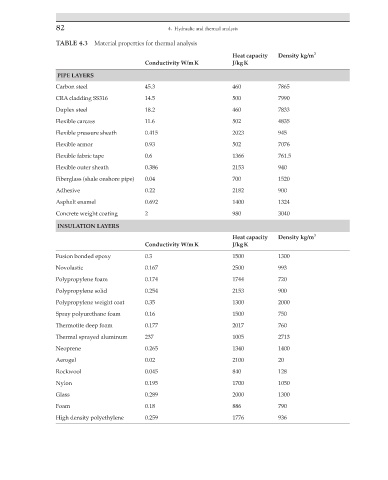

TABLE 4.3 Material properties for thermal analysis

Heat capacity Density kg/m 3

Conductivity W/m K J/kg K

PIPE LAYERS

Carbon steel 45.3 460 7865

CRA cladding SS316 14.5 500 7990

Duplex steel 18.2 460 7833

Flexible carcass 11.6 502 4835

Flexible pressure sheath 0.415 2023 945

Flexible armor 0.93 502 7076

Flexible fabric tape 0.6 1366 761.5

Flexible outer sheath 0.386 2153 940

Fiberglass (shale onshore pipe) 0.04 700 1520

Adhesive 0.22 2182 900

Asphalt enamel 0.692 1400 1324

Concrete weight coating 2 980 3040

INSULATION LAYERS

Heat capacity Density kg/m 3

Conductivity W/m K J/kg K

Fusion bonded epoxy 0.3 1500 1300

Novolastic 0.167 2500 993

Polypropylene foam 0.174 1744 720

Polypropylene solid 0.254 2153 900

Polypropylene weight coat 0.35 1300 2000

Spray polyurethane foam 0.16 1500 750

Thermotite deep foam 0.177 2017 760

Thermal sprayed aluminum 237 1005 2713

Neoprene 0.265 1340 1400

Aerogel 0.02 2100 20

Rockwool 0.045 840 128

Nylon 0.195 1700 1050

Glass 0.289 2000 1300

Foam 0.18 886 790

High density polyethylene 0.259 1776 936