Page 125 - Handbook of Adhesion Promoters

P. 125

118 Properties of Adhesion Promoters

Outstanding properties: improved adhesion between glass filler and the nylon matrix. At low

concentrations of 3.5-7%, increased Notched Izod impact strength of the glass-reinforced nylon

by as much as 30 to 50%, also reduced compound melt viscosity for improved mold filling and

better surface appearance of the glass-filled molded parts. Filled compounds can retain more of

their mechanical properties such as tensile strength, modulus, and heat deformation temperature.

Improved strength and increased moisture resistance in wood/polyethylene composites at signifi-

cantly lower usage levels than conventional maleic anhydride coupling agents. It provides superior

performance and dramatic reduction in water absorption. Balanced attraction between polar fillers/

reinforcements and non-polar polymers. Increased most physical properties of fiberglass-rein-

forced nylon composites. Increased the strength of composites that utilize reinforcements/fillers

such as glass, talc, calcium carbonate, and metals. Optimized interfacial tension, stabilized mor-

phology against high stresses and enhanced adhesion between the phases in the solid state. Com-

patibilization improved the mechanical properties of the polymer blend.

Recommended for resins: cellulose, ABS, EMA, EVA, EVOH, HDPE, HIPS, LDPE, LLDPE,

PA, PC, PE, PO, polyester, PP, rubber, TPO

Recommended for products: cable and wire, paper, packaging, pipe coating, reinforced plastics

composites in automotive, building and construction and wood plastics composite, film, coatings

Recommended applications: intermediate performance, all-purpose PA modifier; adhesion pro-

moter, filled PA compounds; coupling agent for nonhalogen, flame-retarded wire & cable com-

pounds containing fillers such as aluminum trihydrate or magnesium hydroxide; compatibilizer

Processing methods: extrusion coating, injection molding; twin screw extruders with a mild screw

configuration and vacuum degassing facility for good dispersion in styrenic polymer; blown or

cast film

Typical dose: 1-5

Food approval (FDA): 21CFR 175.105/may be used as components of articles intended for use in

packaging, transporting, or holding food, subject to the limitations and requirements therein; U.S.

FDA FAR 21 CFR 177.1520 (c) 6

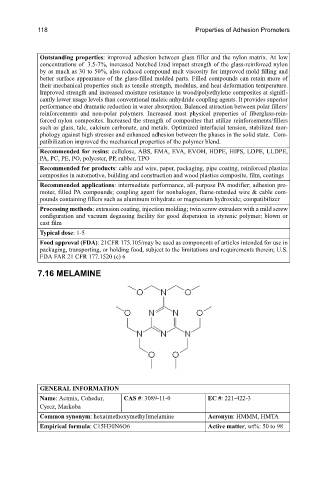

7.16 MELAMINE

GENERAL INFORMATION

Name: Actmix, Cohedur, CAS #: 3089-11-0 EC #: 221-422-3

Cyrez, Markoba

Common synonym: hexa(methoxymethyl)melamine Acronym: HMMM, HMTA

Empirical formula: C15H30N6O6 Active matter, wt%: 50 to 98