Page 122 - Handbook of Adhesion Promoters

P. 122

7.14 Lignin 115

ICAO/IATA class: Environmentally Hazardous Substance, Liquid, n.o.s. (contains dibutyl phtha-

late) 9, III

3

LD50, dermal rabbit, mg/kg: >2000 LC50 inhalation, rat, mg/m :

4250

UN risk phrases, R: R20,R36/38,R42/43,R50,R60,R61 UN/NA class: 3082

USE

Manufacturer: Akcros Chemicals/ Valtris

Outstanding properties: possess minimal influence on initial plastisol viscosity, low odour, no

flammable solvents, high bond strengths.

Recommended for resins: PVC, rigid PVC

Recommended for products: fibers, textiles, carpets, coated fabrics, conveyor belts, certain types

of floor coverings

Recommended applications: adhesion promoter, used in coated fabrics, improved adhesion of

PVC plastisols to polyester, nylon and other synthetic fiber fabrics; highly effective as a bonding

agent to increase adhesion between a PVC plastisol and synthetic fabrics such as polyesters and

polyamides. Areas of application include tarpaulins, protective clothing, marquees, conveyor belts

and certain types of floor covering.

Processing methods: coating

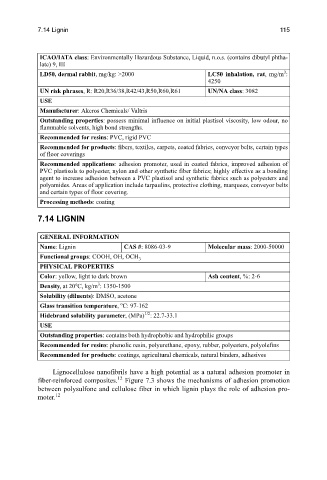

7.14 LIGNIN

GENERAL INFORMATION

Name: Lignin CAS #: 8086-03-9 Molecular mass: 2000-50000

Functional groups: COOH, OH, OCH 3

PHYSICAL PROPERTIES

Color: yellow, light to dark brown Ash content, %: 2-6

3

o

Density, at 20 C, kg/m : 1350-1500

Solubility (diluents): DMSO, acetone

o

Glass transition temperature, C: 97-162

1/2

Hidebrand solubility parameter, (MPa) : 22.7-33.1

USE

Outstanding properties: contains both hydrophobic and hydrophilic groups

Recommended for resins: phenolic resin, polyurethane, epoxy, rubber, polyesters, polyolefins

Recommended for products: coatings, agricultural chemicals, natural binders, adhesives

Lignocellulose nanofibrils have a high potential as a natural adhesion promoter in

12

fiber-reinforced composites. Figure 7.3 shows the mechanisms of adhesion promotion

between polysulfone and cellulose fiber in which lignin plays the role of adhesion pro-

12

moter.