Page 117 - Handbook of Adhesion Promoters

P. 117

110 Properties of Adhesion Promoters

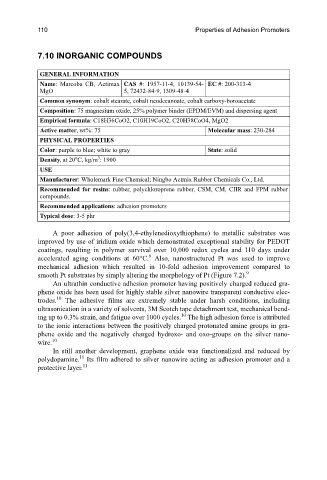

7.10 INORGANIC COMPOUNDS

GENERAL INFORMATION

Name: Marcoba CB, Actimax CAS #: 1957-11-4, 10139-54- EC #: 200-313-4

MgO 5, 72432-84-9, 1309-48-4

Common synonym: cobalt stearate, cobalt neodecanoate, cobalt carboxy-boroacetate

Composition: 75 magnesium oxide, 25% polymer binder (EPDM/EVM) and dispersing agent

Empirical formula: C18H36CoO2, C10H19CoO2, C20H38CoO4, MgO2

Active matter, wt%: 75 Molecular mass: 230-284

PHYSICAL PROPERTIES

Color: purple to blue; white to gray State: solid

o

3

Density, at 20 C, kg/m : 1900

USE

Manufacturer: Wholemark Fine Chemical; Ningbo Actmix Rubber Chemicals Co., Ltd.

Recommended for resins: rubber, polychloroprene rubber, CSM, CM, CIIR and FPM rubber

compounds.

Recommended applications: adhesion promoters

Typical dose: 3-5 phr

A poor adhesion of poly(3,4-ethylenedioxythiophene) to metallic substrates was

improved by use of iridium oxide which demonstrated exceptional stability for PEDOT

coatings, resulting in polymer survival over 10,000 redox cycles and 110 days under

9

accelerated aging conditions at 60°C. Also, nanostructured Pt was used to improve

mechanical adhesion which resulted in 10-fold adhesion improvement compared to

9

smooth Pt substrates by simply altering the morphology of Pt (Figure 7.2).

An ultrathin conductive adhesion promoter having positively charged reduced gra-

phene oxide has been used for highly stable silver nanowire transparent conductive elec-

10

trodes. The adhesive films are extremely stable under harsh conditions, including

ultrasonication in a variety of solvents, 3M Scotch tape detachment test, mechanical bend-

10

ing up to 0.3% strain, and fatigue over 1000 cycles. The high adhesion force is attributed

to the ionic interactions between the positively charged protonated amine groups in gra-

phene oxide and the negatively charged hydroxo- and oxo-groups on the silver nano-

10

wire.

In still another development, graphene oxide was functionalized and reduced by

11

polydopamine. Its film adhered to silver nanowire acting as adhesion promoter and a

11

protective layer.