Page 119 - Handbook of Adhesion Promoters

P. 119

112 Properties of Adhesion Promoters

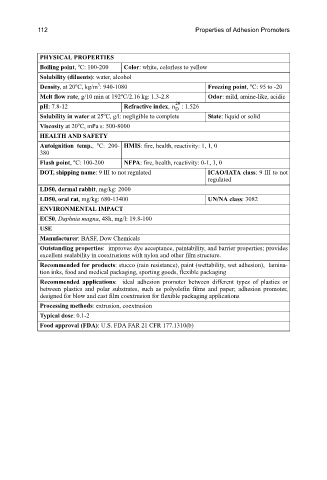

PHYSICAL PROPERTIES

o

Boiling point, C: 100-200 Color: white, colorless to yellow

Solubility (diluents): water, alcohol

3

o

o

Density, at 20 C, kg/m : 940-1080 Freezing point, C: 95 to -20

o

Melt flow rate, g/10 min at 192 C/2.16 kg: 1.3-2.8 Odor: mild, amine-like, acidic

20

pH: 7.8-12 Refractive index, n D : 1.526

o

Solubility in water at 25 C, g/l: negligible to complete State: liquid or solid

o

Viscosity at 20 C, mPa s: 500-8000

HEALTH AND SAFETY

o

Autoignition temp., C: 200- HMIS: fire, health, reactivity: 1, 1, 0

380

o

Flash point, C: 100-200 NFPA: fire, health, reactivity: 0-1, 1, 0

DOT, shipping name: 9 III to not regulated ICAO/IATA class: 9 III to not

regulated

LD50, dermal rabbit, mg/kg: 2000

LD50, oral rat, mg/kg: 680-13400 UN/NA class: 3082

ENVIRONMENTAL IMPACT

EC50, Daphnia magna, 48h, mg/l: 19.8-100

USE

Manufacturer: BASF, Dow Chemicals

Outstanding properties: improves dye acceptance, paintability, and barrier properties; provides

excellent sealability in coextrusions with nylon and other film structure.

Recommended for products: stucco (rain resistance), paint (wettability, wet adhesion), lamina-

tion inks, food and medical packaging, sporting goods, flexible packaging

Recommended applications: ideal adhesion promoter between different types of plastics or

between plastics and polar substrates, such as polyolefin films and paper; adhesion promoter,

designed for blow and cast film coextrusion for flexible packaging applications

Processing methods: extrusion, coextrusion

Typical dose: 0.1-2

Food approval (FDA): U.S. FDA FAR 21 CFR 177.1310(b)