Page 121 - Handbook of Adhesion Promoters

P. 121

114 Properties of Adhesion Promoters

USE

Manufacturer: Evonik, Covestro/formerly Bayer, Vanderbilt

Outstanding properties: provides excellent plastisol rheological performance, high tensile

strength and 130°C cure.

Recommended for resins: low bake PVC plastisols

Recommended for products: furniture, footwear, packaging, construction

Recommended applications: adhesion promoters designed to provide adhesion to electrode posi-

tion primers used in the manufacture of automobiles, trucks and buses. Used in conjunction with

o

small amount of polyamidoamine adhesion promoter. It cures at 120 C with an addition of zinc

octoate catalyst. Highly effective crosslinker for adhesives based on Desmocoll, natural or syn-

thetic rubber with special adhesion on rubber materials. Used in the production of contact and

heat-activated adhesives, as well as reactive and hot-melt adhesives for the transportation, furni-

ture, footwear, packaging, and construction markets.

Processing methods: coating

Typical dose: 3-6

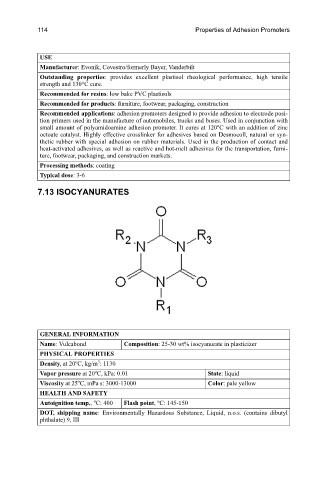

7.13 ISOCYANURATES

GENERAL INFORMATION

Name: Vulcabond Composition: 25-30 wt% isocyanurate in plasticizer

PHYSICAL PROPERTIES

o

3

Density, at 20 C, kg/m : 1130

o

Vapor pressure at 20 C, kPa: 0.01 State: liquid

o

Viscosity at 25 C, mPa s: 3000-13000 Color: pale yellow

HEALTH AND SAFETY

o

o

Autoignition temp., C: 400 Flash point, C: 145-150

DOT, shipping name: Environmentally Hazardous Substance, Liquid, n.o.s. (contains dibutyl

phthalate) 9, III