Page 131 - Handbook of Adhesion Promoters

P. 131

124 Properties of Adhesion Promoters

PHYSICAL PROPERTIES

Acid #, mg KOH/g: 1-15 Hydroxyl number, mg KOH/g: 120-190

o

Boiling point, C: >200 Color: clear, light yellow, brown

3

o

Density, at 20 C, kg/m : 1020- Color, Gardner scale: 2 Color, Pt-Co scale: <50 - <80

1100

Solubility (diluents): toluene, xylene, ethyl acetate, n-butyl acetate, MEK, acetate, propylene gly-

col monomethyl ether

o

o

Glass transition temperature, C: -75 to +80 Melting point, C: 42

o

Melt flow rate, g/10 min at 192 C/2.16 kg: 1.02-1.03 Odor: mild; acidic

o

Solubility in water at 25 C, g/l: insoluble

o

Vapor pressure at 20 C, kPa: <0.01

o

Viscosity at 25 C, mPa s: 350-13000

HEALTH AND SAFETY

HMIS: fire, health, reactivity: 1, 1, 0

o

Flash point, C: >200 NFPA: fire, health, reactivity: 1, 1, 0

DOT, shipping name: not regulated

TDG class: not regulated ICAO/IATA class: not regulated

USE

Manufacturer: Coim, Croda, Elementies/Deuchem, Invista, Polychem Resins

Outstanding properties: compatibility with polyethers, additives and blowers; excellent wetting

of rigid and fibrous substrates providing hardness, flexibility and good adhesion, good pigment

dispersability; good light stability, chalking resistance and good gloss retention; cost competitive

in comparison to conventional polyols; have similar hydroxyl values to castor oil, and can be sub-

stituted on a nearly equal weight basis

Recommended for resins: PU

Recommended for products: adhesives, coatings, automobile refinish, transportation and indus-

trial applications, metal coating, wood finish

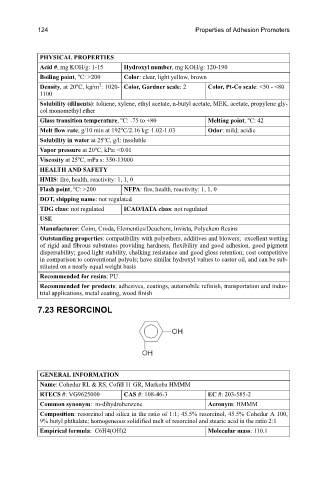

7.23 RESORCINOL

GENERAL INFORMATION

Name: Cohedur RL & RS, Cofill 11 GR, Markoba HMMM

RTECS #: VG9625000 CAS #: 108-46-3 EC #: 203-585-2

Common synonym: m-dihydrobenzene Acronym: HMMM

Composition: resorcinol and silica in the ratio of 1:1; 45.5% resorcinol, 45.5% Cohedur A 100,

9% butyl phthalate; homogeneous solidified melt of resorcinol and stearic acid in the ratio 2:1

Empirical formula: C6H4(OH)2 Molecular mass: 110.1