Page 203 - Handbook of Adhesion Promoters

P. 203

196 Selection of Adhesion Promoters for Different

9.15 ELECTRONICS

Electronics is one of the main applications of adhesive promoters. The following commer-

cial products are proposed for these applications: Bomar BR-970BT & BR-742S,

Chartwell B-515.1, B-515.1/2H, B-517.4, & C-515.72.HR, Dow Corning Z-6128, Dyna-

sylan 1189, Eastman CP, Silquest A-1871, and Sipomer PAM 100. Their main active com-

ponents are based on aliphatic & polyester urethane acrylates, chlorinated polyolefins,

phosphate esters of polyethylene glycol monomethacrylate, and amino-, carboxy-, epoxy-,

and vinyl-silanes.

Liquid crystal polymers and silicone adhesives are widely used in electronics manu-

1

facturing. Their adhesion is critical to the reliability of electronic products. The adhesion

1

is based on hydrogen bonds. The humidity significantly weakens the adhesion strength

1

because it interferes with hydrogen bonding. The weakened adhesion strength can be

1

recovered by removing the moisture from the interface.

In the resist lithography, polyallylamine was used as an effective adhesion promoter

2

between wafer and epoxy resin.

Polydopamine-functionalized graphene was used as a conductive adhesion promoter

3

and a protective layer for silver nanowire transparent electrodes with good results. Long-

3

term stability of optoelectronic devices was improved.

A silane-based adhesion promoter was found suitable for a multi-dielectric-layer

4

coating on a digital microfluidic chip. It improved a chip lifetime by more than 100 times

via transforming the bonding of the dielectric layers (Ta O and Parylene C) from nonspe-

2

5

4

4

cific to chemical. Figure 2.25 shows the mechanism of adhesion promotion.

The combination of an adhesion promoter (3-methacryloxypropyltrimethoxysilane)

and a thermal treatment improves the adhesion of Parylene to silicon substrates in produc-

5

tion microelectromechanical systems.

A poor adhesion of poly(3,4-ethylenedioxythiophene) to metallic substrates was

6

improved by the use of iridium oxide. Figure 8.6 shows the mechanism of adhesion

6

improvement.

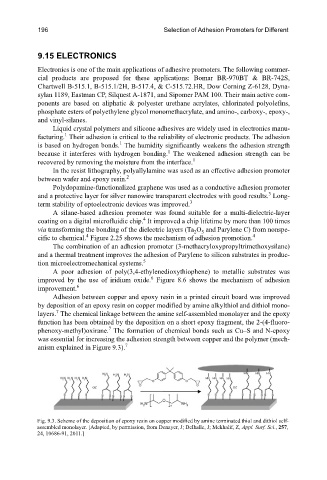

Adhesion between copper and epoxy resin in a printed circuit board was improved

by deposition of an epoxy resin on copper modified by amine alkylthiol and dithiol mono-

7

layers. The chemical linkage between the amine self-assembled monolayer and the epoxy

function has been obtained by the deposition on a short epoxy fragment, the 2-(4-fluoro-

7

phenoxy-methyl)oxirane. The formation of chemical bonds such as Cu–S and N-epoxy

was essential for increasing the adhesion strength between copper and the polymer (mech-

7

anism explained in Figure 9.3).

Fig. 9.3. Scheme of the deposition of epoxy resin on copper modified by amine terminated thiol and dithiol self-

assembled monolayer. [Adapted, by permission, from Denayer, J; Delhalle, J; Mekhalif, Z, Appl. Surf. Sci., 257,

24, 10686-91, 2011.]