Page 62 - Handbook of Adhesion Promoters

P. 62

4

Substrates − Surface Condition

and Treatment

4.1 SURFACE EVALUATION

It is generally accepted that the surface of material affects adhesion but most of the under-

standing comes from studies of surface roughness or its chemistry (especially this modi-

fied by various treatment methods which are discussed below). It becomes more evident

that there are numerous other factors which may influence adhesion which are either

unknown or not included in consideration. Some known examples of these factors are dis-

cussed in this opening section to show that there are still many significant influences

which must be characterized to understand some peculiarities of adhesion process.

Studies on adhesion between isotactic polypropylene and polyamide-6 show that

adhesion depends on molecular weight, crystalline structure, and molecular architecture

1

1,2

developed under selected annealing conditions. According to this study, polymer has to

have sufficient molecular weight to transfer stress from interface to bulk to be dissipated.

The failure mechanism of plasma-treated poly(ethylene terephthalate) depended on a

series of interactions between the indenter and the coating. The geometry of the indenter

3

tip has a profound effect on the results. Plasma treatments settings (e.g., gas composition

and plasma conditions) determine the effect of ions, electrons, fast radicals on etching,

2

activation, and crosslinking on polymer surface. Plasma polymerization can be used to

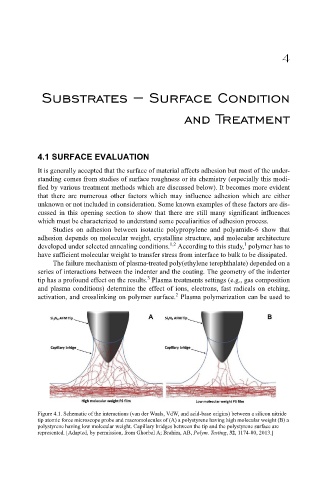

Figure 4.1. Schematic of the interactions (van der Waals, VdW, and acid-base origins) between a silicon nitride

tip atomic force microscope probe and macromolecules of (A) a polystyrene having high molecular weight (B) a

polystyrene having low molecular weight. Capillary bridges between the tip and the polystyrene surface are

represented. [Adapted, by permission, from Ghorbal A; Brahim, AB, Polym. Testing, 32, 1174-80, 2013.]