Page 92 - Handbook of Adhesion Promoters

P. 92

5.7 Metal 85

30

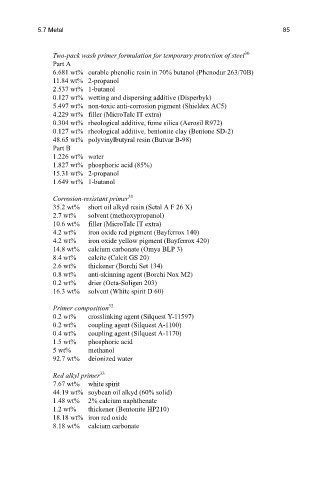

Two-pack wash primer formulation for temporary protection of steel

Part A

6.681 wt% curable phenolic resin in 70% butanol (Phenodur 263/70B)

11.84 wt% 2-propanol

2.537 wt% 1-butanol

0.127 wt% wetting and dispersing additive (Disperbyk)

5.497 wt% non-toxic anti-corrosion pigment (Shieldex AC5)

4.229 wt% filler (MicroTalc IT extra)

0.304 wt% rheological additive, fume silica (Aerosil R972)

0.127 wt% rheological additive, bentonite clay (Bentone SD-2)

48.65 wt% polyvinylbutyral resin (Butvar B-98)

Part B

1.226 wt% water

1.827 wt% phosphoric acid (85%)

15.31 wt% 2-propanol

1.649 wt% 1-butanol

31

Corrosion-resistant primer

35.2 wt% short oil alkyd resin (Setal A F 26 X)

2.7 wt% solvent (methoxypropanol)

10.6 wt% filler (MicroTalc IT extra)

4.2 wt% iron oxide red pigment (Bayferrox 140)

4.2 wt% iron oxide yellow pigment (Bayferrox 420)

14.8 wt% calcium carbonate (Omya BLP 3)

8.4 wt% calcite (Calcit GS 20)

2.6 wt% thickener (Borchi Set 134)

0.8 wt% anti-skinning agent (Borchi Nox M2)

0.2 wt% drier (Octa-Soligen 203)

16.3 wt% solvent (White spirit D 60)

32

Primer composition

0.2 wt% crosslinking agent (Silquest Y-11597)

0.2 wt% coupling agent (Silquest A-1100)

0.4 wt% coupling agent (Silquest A-1170)

1.5 wt% phosphoric acid

5 wt% methanol

92.7 wt% deionized water

33

Red alkyl primer

7.67 wt% white spirit

44.19 wt% soybean oil alkyd (60% solid)

1.48 wt% 2% calcium naphthenate

1.2 wt% thickener (Bentonite HP210)

18.18 wt% iron red oxide

8.18 wt% calcium carbonate