Page 87 - Handbook of Adhesion Promoters

P. 87

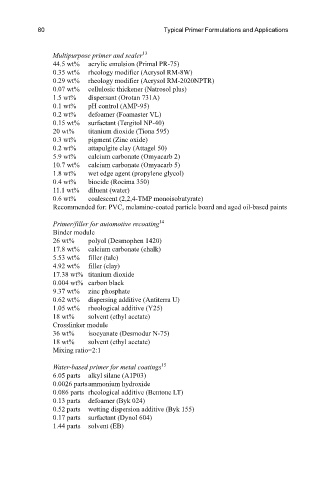

80 Typical Primer Formulations and Applications

13

Multipurpose primer and sealer

44.5 wt% acrylic emulsion (Primal PR-75)

0.35 wt% rheology modifier (Acrysol RM-8W)

0.29 wt% rheology modifier (Acrysol RM-2020NPTR)

0.07 wt% cellulosic thickener (Natrosol plus)

1.5 wt% dispersant (Orotan 731A)

0.1 wt% pH control (AMP-95)

0.2 wt% defoamer (Foamaster VL)

0.15 wt% surfactant (Tergitol NP-40)

20 wt% titanium dioxide (Tiona 595)

0.3 wt% pigment (Zinc oxide)

0.2 wt% attapulgite clay (Attagel 50)

5.9 wt% calcium carbonate (Omyacarb 2)

10.7 wt% calcium carbonate (Omyacarb 5)

1.8 wt% wet edge agent (propylene glycol)

0.4 wt% biocide (Rocima 350)

11.1 wt% diluent (water)

0.6 wt% coalescent (2,2,4-TMP monoisobutyrate)

Recommended for: PVC, melamine-coated particle board and aged oil-based paints

14

Primer/filler for automotive recoating

Binder module

26 wt% polyol (Desmophen 1420)

17.8 wt% calcium carbonate (chalk)

5.53 wt% filler (talc)

4.92 wt% filler (clay)

17.38 wt% titanium dioxide

0.004 wt% carbon black

9.37 wt% zinc phosphate

0.62 wt% dispersing additive (Antiterra U)

1.05 wt% rheological additive (Y25)

18 wt% solvent (ethyl acetate)

Crosslinker module

36 wt% isocyanate (Desmodur N-75)

18 wt% solvent (ethyl acetate)

Mixing ratio=2:1

15

Water-based primer for metal coatings

6.05 parts alkyl silane (A1P03)

0.0026 partsammonium hydroxide

0.086 parts rheological additive (Bentone LT)

0.13 parts defoamer (Byk 024)

0.52 parts wetting dispersion additive (Byk 155)

0.17 parts surfactant (Dynol 604)

1.44 parts solvent (EB)