Page 85 - Handbook of Adhesion Promoters

P. 85

78 Typical Primer Formulations and Applications

0.04 wt% optical brightener (Uvitex OB)

56.9 wt% solvent (MEK)

15 wt% solvent (toluene)

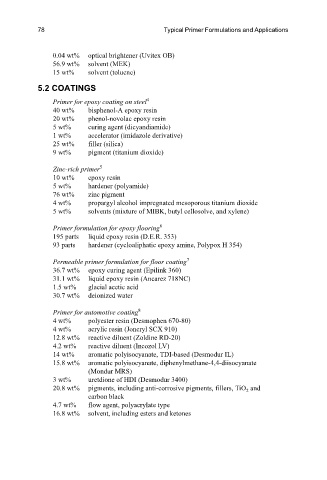

5.2 COATINGS

4

Primer for epoxy coating on steel

40 wt% bisphenol-A epoxy resin

20 wt% phenol-novolac epoxy resin

5 wt% curing agent (dicyandiamide)

1 wt% accelerator (imidazole derivative)

25 wt% filler (silica)

9 wt% pigment (titanium dioxide)

5

Zinc-rich primer

10 wt% epoxy resin

5 wt% hardener (polyamide)

76 wt% zinc pigment

4 wt% propargyl alcohol impregnated mesoporous titanium dioxide

5 wt% solvents (mixture of MIBK, butyl cellosolve, and xylene)

6

Primer formulation for epoxy flooring

195 parts liquid epoxy resin (D.E.R. 353)

93 parts hardener (cycloaliphatic epoxy amine, Polypox H 354)

7

Permeable primer formulation for floor coating

36.7 wt% epoxy curing agent (Epilink 360)

31.1 wt% liquid epoxy resin (Ancarez 718NC)

1.5 wt% glacial acetic acid

30.7 wt% deionized water

8

Primer for automotive coating

4 wt% polyester resin (Desmophen 670-80)

4 wt% acrylic resin (Joncryl SCX 910)

12.8 wt% reactive diluent (Zoldine RD-20)

4.2 wt% reactive diluent (Incozol LV)

14 wt% aromatic polyisocyanate, TDI-based (Desmodur IL)

15.8 wt% aromatic polyisocyanate, diphenylmethane-4,4-diisocyanate

(Mondur MRS)

3 wt% uretdione of HDI (Desmodur 3400)

20.8 wt% pigments, including anti-corrosive pigments, fillers, TiO and

2

carbon black

4.7 wt% flow agent, polyacrylate type

16.8 wt% solvent, including esters and ketones