Page 88 - Handbook of Adhesion Promoters

P. 88

5.3 Coil coating 81

3.4 parts epoxy resin (Epi-rez 3510)

0.85 parts carbon black (Monolite)

5.1 parts block copolymer surfactant (30% Pluronic F87)

6.05 parts anti-corrosive pigment (Shieldex)

0.81 parts 10% sodium nitrite

0.46 parts surfactant (Surfynol 104)

20.37 parts talc

0.0937 partssolvent (Texanol)

15.41 parts water

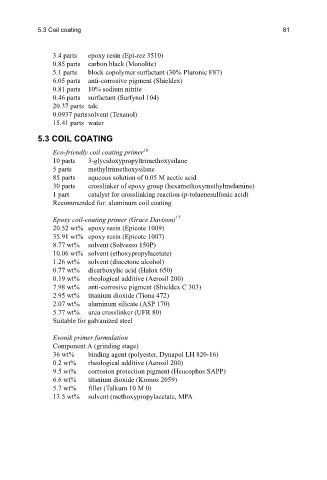

5.3 COIL COATING

16

Eco-friendly coil coating primer

10 parts 3-glycidoxypropyltrimethoxysilane

5 parts methyltrimethoxysilane

85 parts aqueous solution of 0.05 M acetic acid

30 parts crosslinker of epoxy group (hexamethoxymethylmelamine)

1 part catalyst for crosslinking reaction (p-toluenesulfonic acid)

Recommended for: aluminum coil coating

17

Epoxy coil-coating primer (Grace Davison)

20.52 wt% epoxy resin (Epicote 1009)

35.91 wt% epoxy resin (Epicote 1007)

8.77 wt% solvent (Solvesso 150P)

10.06 wt% solvent (ethoxypropylacetate)

1.26 wt% solvent (diacetone alcohol)

0.77 wt% dicarboxylic acid (Halox 650)

0.19 wt% rheological additive (Aerosil 200)

7.98 wt% anti-corrosive pigment (Shieldex C 303)

2.95 wt% titanium dioxide (Tiona 472)

2.07 wt% aluminum silicate (ASP 170)

5.77 wt% urea crosslinker (UFR 80)

Suitable for galvanized steel

Evonik primer formulation

Component A (grinding stage)

36 wt% binding agent (polyester, Dynapol LH 820-16)

0.2 wt% rheological additive (Aerosil 200)

9.5 wt% corrosion protection pigment (Heucophos SAPP)

6.6 wt% titanium dioxide (Kronos 2059)

5.7 wt% filler (Talkum 10 M 0)

13.5 wt% solvent (methoxypropylacetate, MPA