Page 105 - Handbook of Adhesives and Sealants

P. 105

Theories of Adhesion 73

Polyamide-

Imide

Epoxy

Adhesive

Stainless

Steel

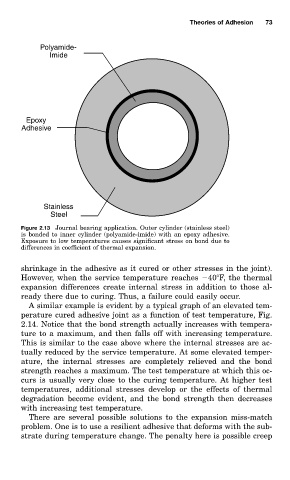

Figure 2.13 Journal bearing application. Outer cylinder (stainless steel)

is bonded to inner cylinder (polyamide-imide) with an epoxy adhesive.

Exposure to low temperatures causes significant stress on bond due to

differences in coefficient of thermal expansion.

shrinkage in the adhesive as it cured or other stresses in the joint).

However, when the service temperature reaches 40 F, the thermal

expansion differences create internal stress in addition to those al-

ready there due to curing. Thus, a failure could easily occur.

A similar example is evident by a typical graph of an elevated tem-

perature cured adhesive joint as a function of test temperature, Fig.

2.14. Notice that the bond strength actually increases with tempera-

ture to a maximum, and then falls off with increasing temperature.

This is similar to the case above where the internal stresses are ac-

tually reduced by the service temperature. At some elevated temper-

ature, the internal stresses are completely relieved and the bond

strength reaches a maximum. The test temperature at which this oc-

curs is usually very close to the curing temperature. At higher test

temperatures, additional stresses develop or the effects of thermal

degradation become evident, and the bond strength then decreases

with increasing test temperature.

There are several possible solutions to the expansion miss-match

problem. One is to use a resilient adhesive that deforms with the sub-

strate during temperature change. The penalty here is possible creep