Page 106 - Handbook of Adhesives and Sealants

P. 106

74 Chapter Two

Approximate

Cure

Temperature

Shear

Strength, psi

Test Temperature

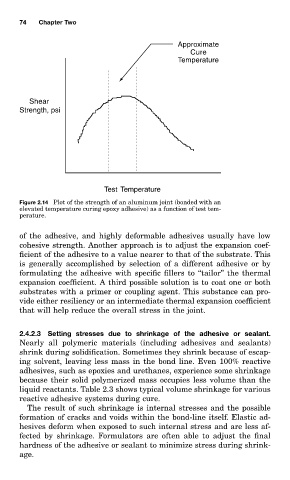

Figure 2.14 Plot of the strength of an aluminum joint (bonded with an

elevated temperature curing epoxy adhesive) as a function of test tem-

perature.

of the adhesive, and highly deformable adhesives usually have low

cohesive strength. Another approach is to adjust the expansion coef-

ficient of the adhesive to a value nearer to that of the substrate. This

is generally accomplished by selection of a different adhesive or by

formulating the adhesive with specific fillers to ‘‘tailor’’ the thermal

expansion coefficient. A third possible solution is to coat one or both

substrates with a primer or coupling agent. This substance can pro-

vide either resiliency or an intermediate thermal expansion coefficient

that will help reduce the overall stress in the joint.

2.4.2.3 Setting stresses due to shrinkage of the adhesive or sealant.

Nearly all polymeric materials (including adhesives and sealants)

shrink during solidification. Sometimes they shrink because of escap-

ing solvent, leaving less mass in the bond line. Even 100% reactive

adhesives, such as epoxies and urethanes, experience some shrinkage

because their solid polymerized mass occupies less volume than the

liquid reactants. Table 2.3 shows typical volume shrinkage for various

reactive adhesive systems during cure.

The result of such shrinkage is internal stresses and the possible

formation of cracks and voids within the bond-line itself. Elastic ad-

hesives deform when exposed to such internal stress and are less af-

fected by shrinkage. Formulators are often able to adjust the final

hardness of the adhesive or sealant to minimize stress during shrink-

age.