Page 112 - Handbook of Adhesives and Sealants

P. 112

80 Chapter Two

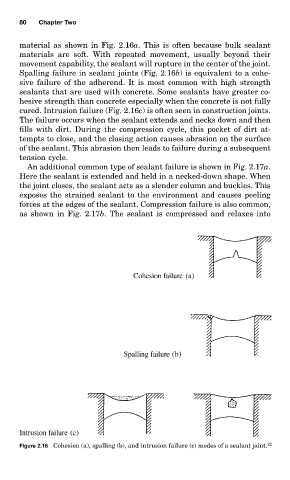

material as shown in Fig. 2.16a. This is often because bulk sealant

materials are soft. With repeated movement, usually beyond their

movement capability, the sealant will rupture in the center of the joint.

Spalling failure in sealant joints (Fig. 2.16b) is equivalent to a cohe-

sive failure of the adherend. It is most common with high strength

sealants that are used with concrete. Some sealants have greater co-

hesive strength than concrete especially when the concrete is not fully

cured. Intrusion failure (Fig. 2.16c) is often seen in construction joints.

The failure occurs when the sealant extends and necks down and then

fills with dirt. During the compression cycle, this pocket of dirt at-

tempts to close, and the closing action causes abrasion on the surface

of the sealant. This abrasion then leads to failure during a subsequent

tension cycle.

An additional common type of sealant failure is shown in Fig. 2.17a.

Here the sealant is extended and held in a necked-down shape. When

the joint closes, the sealant acts as a slender column and buckles. This

exposes the strained sealant to the environment and causes peeling

forces at the edges of the sealant. Compression failure is also common,

as shown in Fig. 2.17b. The sealant is compressed and relaxes into

Figure 2.16 Cohesion (a), spalling (b), and intrusion failure (c) modes of a sealant joint. 22