Page 113 - Handbook of Adhesives and Sealants

P. 113

Theories of Adhesion 81

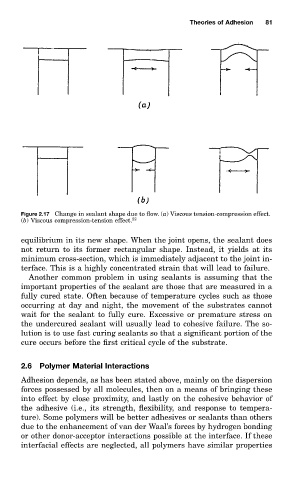

Figure 2.17 Change in sealant shape due to flow. (a) Viscous tension-compression effect.

(b) Viscous compression-tension effect. 22

equilibrium in its new shape. When the joint opens, the sealant does

not return to its former rectangular shape. Instead, it yields at its

minimum cross-section, which is immediately adjacent to the joint in-

terface. This is a highly concentrated strain that will lead to failure.

Another common problem in using sealants is assuming that the

important properties of the sealant are those that are measured in a

fully cured state. Often because of temperature cycles such as those

occurring at day and night, the movement of the substrates cannot

wait for the sealant to fully cure. Excessive or premature stress on

the undercured sealant will usually lead to cohesive failure. The so-

lution is to use fast curing sealants so that a significant portion of the

cure occurs before the first critical cycle of the substrate.

2.6 Polymer Material Interactions

Adhesion depends, as has been stated above, mainly on the dispersion

forces possessed by all molecules, then on a means of bringing these

into effect by close proximity, and lastly on the cohesive behavior of

the adhesive (i.e., its strength, flexibility, and response to tempera-

ture). Some polymers will be better adhesives or sealants than others

due to the enhancement of van der Waal’s forces by hydrogen bonding

or other donor-acceptor interactions possible at the interface. If these

interfacial effects are neglected, all polymers have similar properties