Page 118 - Handbook of Adhesives and Sealants

P. 118

86 Chapter Two

erty of a polymer that depends on its chemical composition and the

degree of crosslinking or molecular interaction.

For good bond strength and creep resistance, the T of the adhesive

g

or sealant should be well above the maximum temperature that it will

see in service. However, peel strength will be low if the T is high. It

g

is very difficult to provide an adhesive that has high peel strength

with good cohesive strength and environmental resistance. This prob-

lem and possible solutions for it will be discussed in detail in following

chapters. A high T will also limit the low temperature properties of

g

the adhesive or sealant. Bond strength at elevated temperatures can

be increased by raising crystallinity, hydrogen bonding, and crosslink-

ing. Typical glass transition temperatures for adhesive resins are

shown in Table 2.4.

There is an interdependence on the rheological characteristics of the

bulk adhesive and its adhesion characteristics. For example, if a co-

hesively weak polymeric material is being used as the adhesive, the

demand on the strength of surface attachment would be much less

than if the adhesive were a tough polymeric blend. Hence, the rheo-

logical strength of the adhesive polymer plays an important role in

determining the magnitude of the joint strength.

Figure 2.21 presents the tensile strength of a carboxylic acid con-

taining acrylic terpolymer as a function of temperature. The glass

transition temperature of this terpolymer is 97 F. The joint strength

of this adhesive is typical of noncrystalline thermoplastic adhesive sys-

tems. In the rubbery range (above T ), the joint strengths are low

g

because the polymer itself is cohesively weak. At lower temperatures,

approaching T , the adhesive-joint strengths increase and are maxi-

g

mized near T . In the glassy region, it has been found that the joint

g

strength depends on how brittle the adhesive material is. If the ad-

hesive is brittle in the glassy state, the adhesive joint strength will

decrease. With tougher plastics or resins like crosslinked epoxies,

there is little or no drop in joint strength immediately below T . Usu-

g

ally a broad maximum joint strength plateau is observed.

From this data, one can now attempt to generalize the effect of the

rheological state on adhesive joint strength. This generalized condition

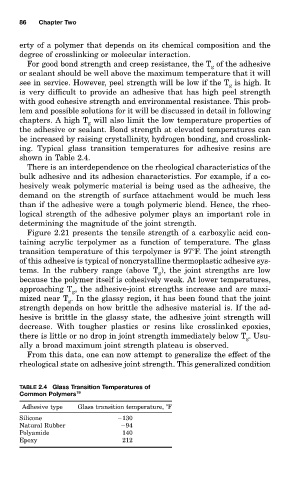

TABLE 2.4 Glass Transition Temperatures of

Common Polymers 19

Adhesive type Glass transition temperature, F

Silicone 130

Natural Rubber 94

Polyamide 140

Epoxy 212