Page 418 - Handbook of Adhesives and Sealants

P. 418

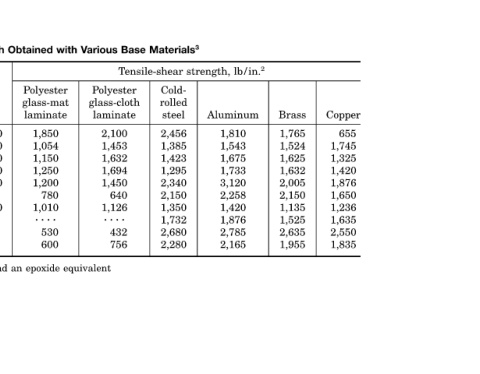

Copper 655 1,745 1,325 1,420 1,876 1,650 1,236 1,635 2,550 1,835

Brass 1,765 1,524 1,625 1,632 2,005 2,150 1,135 1,525 2,635 1,955

lb/in. 2 Aluminum 1,810 1,543 1,675 1,733 3,120 2,258 1,420 1,876 2,785 2,165

strength,

Materials 3 Cold- rolled steel 2,456 1,385 1,423 1,295 2,340 2,150 1,350 1,732 2,680 2,280

Base Tensile-shear 640 432 756

Various Polyester glass-cloth laminate 2,100 1,453 1,632 1,694 1,450 1,126 equivalent

with 780 530 600

Obtained Polyester glass-mat laminate 1,850 1,054 1,150 1,250 1,200 1,010 epoxide an

Strength cycle, F 150 at 4 150 at 4 150 at 4 150 at 4 150 at 4 150 at 4 had and

Bond Cure hat 75, at 75, at 75, at 75, at 75, at 350 at 75, at 375 at 350 at 350 at

the 24 24 24 24 24 4 24 3 4 6 epichlorohydrin

on

Agents Amount* 6 6 12 5 35–65 12.5 11 3 85 and A

Curing . . bisphenol filler.

Epoxy ..................... ................ .................. monoethylamine..... ...................... from adhesives contained no resin.

The Influence of agent Curing Triethylamine ....................... Pyrrolidine .......................... equivalent 210–230 Metaphenylenidiamine............... anhydride

TABLE 10.7 Trimethylamine Triethylenetetramine amine Polyamid Diethylenetriamine trifluoride Boron Dicyandiamide nadic Methyl resin Epoxy 195; the 180 to of 100