Page 420 - Handbook of Adhesives and Sealants

P. 420

use F

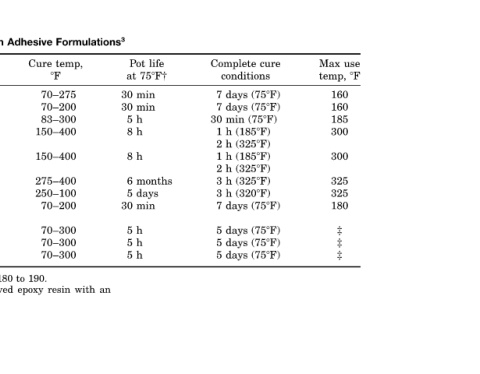

Max temp, 160 160 185 300 300 325 325 180 ‡ ‡ ‡

cure (75 F) (75 F) (75 F) (185 F) (325 F) (185 F) (325 F) (325 F) (320 F) (75 F) (75 F) (75 F) (75 F)

Complete conditions days 7 days 7 min 30 h 1 h 2 h 1 h 2 h 3 h 3 days 7 days 5 days 5 days 5

life 75 F† months days

Pot at min 30 min 30 h 5 h 8 h 8 6 5 min 30 h 5 h 5 h 5 an

Adhesive Formulations 3 temp, Cure F 70–275 70–200 83–300 150–400 150–400 275–400 250–100 70–200 70–300 70–300 70–300 190. with resin

in to 180 epoxy derived

Resins Amount required* 11–13 10–12 6–8 12–14 26–30 1–4 80–100 11–13 30–70 30–70 30–70 equivalent of

Epoxy A–epichlorohydrin

with epoxide

Used Physical form Liquid Liquid Liquid Solid Solid Solid Liquid Liquid Semisolid Liquid Liquid

Agents resin with an bisphenol a

Curing .............. ............ ............... . . epoxy with batch; 190. concentration.

Characteristics of agent Curing Diethylenetriamine ................ Diethylaminopropylamine .......... dianiline monoethylamine anhydride............ Triethylamine.........

TABLE 10.8 Triethylenetetramine Metaphenylenediamine Methylene trifluoride Boron nadic Methyl Polyamides: value Amine value Amine value Amine 100 *Per hundred †