Page 62 - Handbook of Battery Materials

P. 62

28 2 Practical Batteries

progress in alkaline-zinc batteries and manufactured zinc powder with high surface

area to prevent zinc passivation.

The discharge of alkaline-manganese batteries comes from the electrochemical

reactions at the anode and cathode. During discharge, the negative electrode

material, zinc, is oxidized, forming zinc oxide; at the same time, MnO 2 in the

positive electrode is reduced (MnOOH):

Cathode reaction:

2MnO 2 + H 2 O + 2e → 2MnOOH + 2OH − 0.12 V vs NHE (2.1)

−

Anode reaction:

Zn + 2OH → ZnO + H 2 O + 2e − − 1.33 V vs NHE (2.2)

−

Overall reaction:

Zn + 2MnO 2 → ZnO + 2MnOOH 1.45 V (2.3)

The initial voltage of an alkaline-manganese dioxide battery is about 1.5 V.

Alkaline-manganese batteries use a concentrated alkaline aqueous solution (typ-

ically in the range of 30–45% potassium hydroxide) for electrolyte. In this

concentrated electrolyte, the zinc electrode reaction proceeds, but if the con-

centration of the alkaline solution is low, then the zinc tends to passivate.

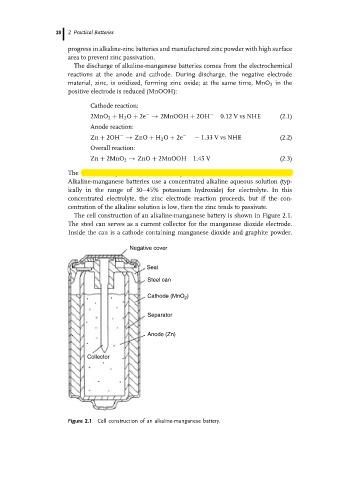

The cell construction of an alkaline-manganese battery is shown in Figure 2.1.

The steel can serves as a current collector for the manganese dioxide electrode.

Inside the can is a cathode containing manganese dioxide and graphite powder.

Negative cover

Seal

Steel can

Cathode (MnO )

2

Separator

Anode (Zn)

Collector

Figure 2.1 Cell construction of an alkaline-manganese battery.