Page 145 - Handbook of Energy Engineering Calculations

P. 145

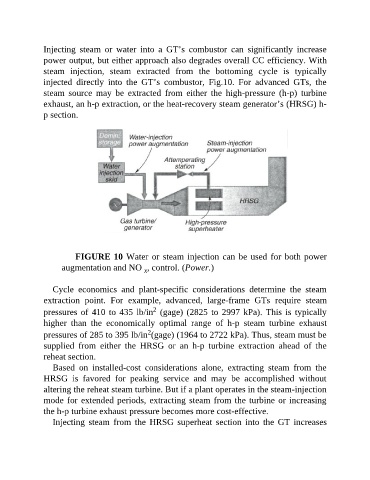

Injecting steam or water into a GT’s combustor can significantly increase

power output, but either approach also degrades overall CC efficiency. With

steam injection, steam extracted from the bottoming cycle is typically

injected directly into the GT’s combustor, Fig.10. For advanced GTs, the

steam source may be extracted from either the high-pressure (h-p) turbine

exhaust, an h-p extraction, or the heat-recovery steam generator’s (HRSG) h-

p section.

FIGURE 10 Water or steam injection can be used for both power

augmentation and NO , control. (Power.)

x

Cycle economics and plant-specific considerations determine the steam

extraction point. For example, advanced, large-frame GTs require steam

2

pressures of 410 to 435 lb/in (gage) (2825 to 2997 kPa). This is typically

higher than the economically optimal range of h-p steam turbine exhaust

2

pressures of 285 to 395 lb/in (gage) (1964 to 2722 kPa). Thus, steam must be

supplied from either the HRSG or an h-p turbine extraction ahead of the

reheat section.

Based on installed-cost considerations alone, extracting steam from the

HRSG is favored for peaking service and may be accomplished without

altering the reheat steam turbine. But if a plant operates in the steam-injection

mode for extended periods, extracting steam from the turbine or increasing

the h-p turbine exhaust pressure becomes more cost-effective.

Injecting steam from the HRSG superheat section into the GT increases