Page 152 - Handbook of Energy Engineering Calculations

P. 152

Specialist, ABCO Industries, Inc., and was presented in Chemical

Engineering magazine.

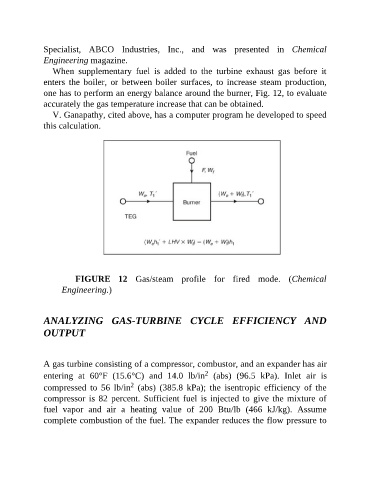

When supplementary fuel is added to the turbine exhaust gas before it

enters the boiler, or between boiler surfaces, to increase steam production,

one has to perform an energy balance around the burner, Fig. 12, to evaluate

accurately the gas temperature increase that can be obtained.

V. Ganapathy, cited above, has a computer program he developed to speed

this calculation.

FIGURE 12 Gas/steam profile for fired mode. (Chemical

Engineering.)

ANALYZING GAS-TURBINE CYCLE EFFICIENCY AND

OUTPUT

A gas turbine consisting of a compressor, combustor, and an expander has air

2

entering at 60°F (15.6°C) and 14.0 lb/in (abs) (96.5 kPa). Inlet air is

2

compressed to 56 lb/in (abs) (385.8 kPa); the isentropic efficiency of the

compressor is 82 percent. Sufficient fuel is injected to give the mixture of

fuel vapor and air a heating value of 200 Btu/lb (466 kJ/kg). Assume

complete combustion of the fuel. The expander reduces the flow pressure to