Page 134 - Handbook of Materials Failure Analysis

P. 134

130 CHAPTER 6 Failure analysis of concrete sleepers/bearers

(a) (b)

(c) (d)

(e) (f)

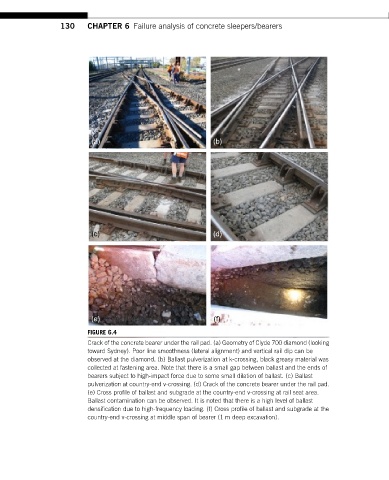

FIGURE 6.4

Crack of the concrete bearer under the rail pad. (a) Geometry of Clyde 700 diamond (looking

toward Sydney). Poor line smoothness (lateral alignment) and vertical rail dip can be

observed at the diamond. (b) Ballast pulverization at k-crossing, black greasy material was

collected at fastening area. Note that there is a small gap between ballast and the ends of

bearers subject to high-impact force due to some small dilation of ballast. (c) Ballast

pulverization at country-end v-crossing. (d) Crack of the concrete bearer under the rail pad.

(e) Cross profile of ballast and subgrade at the country-end v-crossing at rail seat area.

Ballast contamination can be observed. It is noted that there is a high level of ballast

densification due to high-frequency loading. (f) Cross profile of ballast and subgrade at the

country-end v-crossing at middle span of bearer (1 m deep excavation).