Page 250 - Handbook of Materials Failure Analysis

P. 250

246 CHAPTER 10 A reliable analysis method

2 SHOVEL STRUCTURE AND OPERATION PROCESS

2.1 STRUCTURE DESCRIPTION

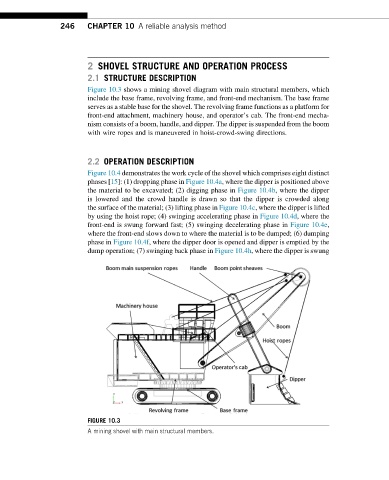

Figure 10.3 shows a mining shovel diagram with main structural members, which

include the base frame, revolving frame, and front-end mechanism. The base frame

serves as a stable base for the shovel. The revolving frame functions as a platform for

front-end attachment, machinery house, and operator’s cab. The front-end mecha-

nism consists of a boom, handle, and dipper. The dipper is suspended from the boom

with wire ropes and is maneuvered in hoist-crowd-swing directions.

2.2 OPERATION DESCRIPTION

Figure 10.4 demonstrates the work cycle of the shovel which comprises eight distinct

phases [15]: (1) dropping phase in Figure 10.4a, where the dipper is positioned above

the material to be excavated; (2) digging phase in Figure 10.4b, where the dipper

is lowered and the crowd handle is drawn so that the dipper is crowded along

the surface of the material; (3) lifting phase in Figure 10.4c, where the dipper is lifted

by using the hoist rope; (4) swinging accelerating phase in Figure 10.4d, where the

front-end is swung forward fast; (5) swinging decelerating phase in Figure 10.4e,

where the front-end slows down to where the material is to be dumped; (6) dumping

phase in Figure 10.4f, where the dipper door is opened and dipper is emptied by the

dump operation; (7) swinging back phase in Figure 10.4h, where the dipper is swung

FIGURE 10.3

A mining shovel with main structural members.