Page 269 - Handbook of Plastics Technologies

P. 269

ELASTOMERS

ELASTOMERS 4.61

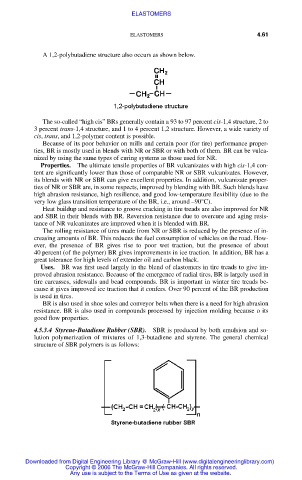

A 1,2-polybutadiene structure also occurs as shown below.

The so-called “high cis” BRs generally contain a 93 to 97 percent cis-1,4 structure, 2 to

3 percent trans-1,4 structure, and 1 to 4 percent 1,2 structure. However, a wide variety of

cis, trans, and 1,2-polymer content is possible.

Because of its poor behavior on mills and certain poor (for tire) performance proper-

ties, BR is mostly used in blends with NR or SBR or with both of them. BR can be vulca-

nized by using the same types of curing systems as those used for NR.

Properties. The ultimate tensile properties of BR vulcanizates with high cis-1,4 con-

tent are significantly lower than those of comparable NR or SBR vulcanizates. However,

its blends with NR or SBR can give excellent properties. In addition, vulcanizate proper-

ties of NR or SBR are, in some respects, improved by blending with BR. Such blends have

high abrasion resistance, high resilience, and good low-temperature flexibility (due to the

very low glass transition temperature of the BR, i.e., around –90°C).

Heat buildup and resistance to groove cracking in tire treads are also improved for NR

and SBR in their blends with BR. Reversion resistance due to overcure and aging resis-

tance of NR vulcanizates are improved when it is blended with BR.

The rolling resistance of tires made from NR or SBR is reduced by the presence of in-

creasing amounts of BR. This reduces the fuel consumption of vehicles on the road. How-

ever, the presence of BR gives rise to poor wet traction, but the presence of about

40 percent (of the polymer) BR gives improvements in ice traction. In addition, BR has a

great tolerance for high levels of extender oil and carbon black.

Uses. BR was first used largely in the blend of elastomers in tire treads to give im-

proved abrasion resistance. Because of the emergence of radial tires, BR is largely used in

tire carcasses, sidewalls and bead compounds. BR is important in winter tire treads be-

cause it gives improved ice traction that it confers. Over 90 percent of the BR production

is used in tires.

BR is also used in shoe soles and conveyor belts when there is a need for high abrasion

resistance. BR is also used in compounds processed by injection molding because o its

good flow properties.

4.5.3.4 Styrene-Butadiene Rubber (SBR). SBR is produced by both emulsion and so-

lution polymerization of mixtures of 1,3-butadiene and styrene. The general chemical

structure of SBR polymers is as follows:

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.