Page 268 - Handbook of Plastics Technologies

P. 268

ELASTOMERS

4.60 CHAPTER 4

New types of catalyst systems that could selectively join together monomer units in a

well ordered fashion were discovered in the 1950s. Shortly after the discovery of the

breakthrough Ziegler-Natta catalyst systems for the polymerization of ethylene, stereo-

specific catalysts were developed for the polymerization of isoprene. This enabled the pro-

duction of a nearly pure cis-1,4-polymer, the so-called “synthetic natural rubber.” In 1962,

®

Goodyear introduced Natsyn , a strain-crystallizable isoprene polymer with a cis-1,4-

content of 98.5 percent.

Properties. Typical raw polymer and vulcanized properties of synthetic IR are similar

to those of NR. Both exhibit good inherent tack, high compounded gum tensile strength

(green strength), and good vulcanizate hysteresis (low values) and tensile properties. In

synthetic IR, there is minimal variance in physical properties lot to lot, and there is a low

concentration of nonrubber constituents compared to natural rubber.

Because of the lower raw polymer viscosity of synthetic polyisoprene, part or the en-

tire breakdown step normally used for natural rubber (premastication) might be elimi-

nated.

Synthetic polyisoprene is especially well suited for injection molded compounds. Be-

cause of its uniform cure rate. Time/temperature press cycles can be established with as-

surance that parts will be uniformly cured.

Uses. Synthetic polyisoprene is used in a variety of applications requiring low water

swell, high gum tensile strength, good resilience, high hot tensile strength, and good tack.

Gum compounds based on synthetic polyisoprene are used in rubber bands, cut thread,

baby bottle nipples, and extruded hose. Black-loaded compounds find use in tires, motor

mounts, pipe gaskets, shock absorber bushings, and many other molded and mechanical

goods. Mineral-filled systems find applications in footwear, sponge, and sporting goods.

In addition, recent concerns about allergic reactions to proteins present in natural rubber

have prompted increased usage of the more pure synthetic polyisoprene in some applica-

tions. Synthetic IR, converted to a latex, is used in the production of nonallergic gloves for

medical and related uses.

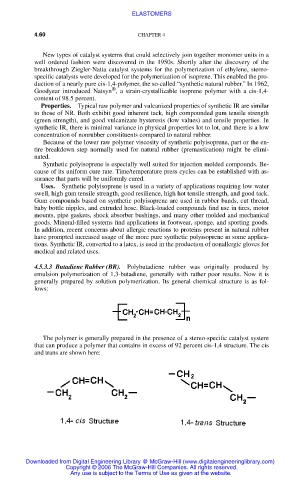

4.5.3.3 Butadiene Rubber (BR). Polybutadiene rubber was originally produced by

emulsion polymerization of 1,3-butadiene, generally with rather poor results. Now it is

generally prepared by solution polymerization. Its general chemical structure is as fol-

lows:

The polymer is generally prepared in the presence of a stereo-specific catalyst system

that can produce a polymer that contains in excess of 92 percent cis-1,4 structure. The cis

and trans are shown here:

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.